resumo

Bark is one of the main wastes of the chemical and mechanical processing of Eucalyptus globulus wood. The proposed biochemical processing of bark via saccharification pathway involves steam explosion (SE) pretreatment (severity factor log R0 of 4.22) followed by enzymatic hydrolysis using an enzymatic cocktail composed of cellulolytic and xylanolytic enzymes. Almost 70% cellulose saccharification was achieved. The remaining cellolignin residue (CLEZ) was analysed for its chemical composition and structural features by conventional wet chemistry methods and a series of spectroscopic tools (FTIR-ATR, solid-state CP/MAS C-13 NMR spectroscopy and wide-angle X-ray scattering (WAXS)). The main CLEZ component (about 51%) is acid-insoluble lignin, the chemical composition of which in terms of the ratio of syringyl (S), guaiacyl (G) and p-hydroxyphenyl (H) units (70:28:2) is very close to that in the initial bark. This lignin is highly condensed and structurally associated with condensed tannins, which makes CLEZ recalcitrant to delignification by common methods. About one third of cellulose in eucalyptus bark after SE was inaccessible to enzymatic hydrolysis and remained in the CLEZ. This cellulose, structurally similar to microcrystalline cellulose, is imbedded into the lignin-tannins condensed matrix and extremely difficult to purify. In contrast to cellulose, bark hemicelluloses were effectively removed in enzymatic hydrolysis, with only small amounts (<2%) remaining in CLEZ. Among other CLEZ ingredients, proteins and inorganic/organic salts were the most abundant. The latter includes noticeable amounts of calcium oxalate phytoliths (up to 9%), Fe and Si salts. The eventual application areas of CLEZ are discussed.

palavras-chave

SOLID-STATE NMR; GRAPE STALKS; CELLULOSE CRYSTALLINITY; LIGNIN; PRETREATMENT; ETHANOL; BIOMASS; SPECTROSCOPY; TECHNOLOGY

categoria

Agriculture

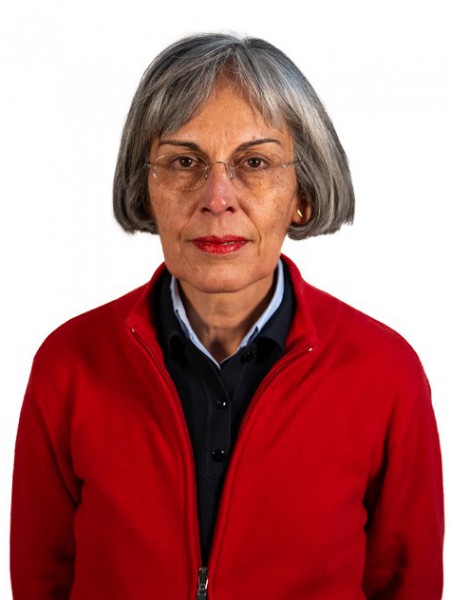

autores

Magina, S; Marques, S; Girio, F; Lourenco, A; Barros-Timmons, A; Evtuguin, DV

nossos autores

Projectos

CICECO - Aveiro Institute of Materials (UIDB/50011/2020)

CICECO - Aveiro Institute of Materials (UIDP/50011/2020)

Associated Laboratory CICECO-Aveiro Institute of Materials (LA/P/0006/2020)

Bioeconomia para Têxtil e Vestuário (BE@T)

Rede Nacional de Ressonância Magnética Nuclear (PTNMR)

Collaboratory for Emerging Technologies, CoLab (EMERGING TECHNOLOGIES)

agradecimentos

This work was developed within the scope of the project CICECO-Aveiro Institute of Materials, UIDB/50011/2020 (DOI 10.54499/UIDB/50011/2020) , UIDP/50011/2020 (DOI 10.54499/UIDP/50011/2020) & LA/P/0006/2020 (DOI 10.54499/LA/P/0006/2020) and CEF, http://doi.org./10.54499/UIDB/00239/2020, both Centres financed by national funds through the FCT/MCTES (PIDDAC) . The authors acknowledge the financial support from Integrated Project BE@t - Textile Bioeconomy, to strengthen the National Bioeconomy, financed by the Environmental Fund through Component 12 - Promotion of Sustainable Bioeconomy (Investment TC-C12-i01 - Sustainable Bioeconomy No. 02/C12-i01/202) , of European funds allocated to Portugal by the Recovery and Resilience Plan (RRP) , within the scope of the European Union (EU) Recovery and Resilience Mechanism, framed in the Next Generation EU, for the period 2021 - 2026. The authors gratefully acknowledge RAIZ - Forest and Paper Research Institute (Eixo, Portugal) for providing the Eucalyptus globulus bark collected from the Navigator company pulp mill (Cacia, Portugal) , and Novozymes (Bagsvaerd, Denmark) for supplying Cellic (R) CTec3 HS. The technical assistance of STEX Company (Aveiro,Portugal) on the operation of pilot scale infrastructure of steam explo-sion and enzymatic hydrolysis is also acknowledged. The NMR spectrometers are part of the National NMR Network (PTNMR) and partially supported by Infrastructure Project N degrees 022161 (co-financed by FEDER through COMPETE 2020, POCI and PORL and FCT through PIDDAC) . A. L. was also supported by FCT through a research contract (http://doi. org/10.54499/DL57/2016/CP1382/CT0007) .r Portugal) on the operation of pilot scale infrastructure of steam explo-sion and enzymatic hydrolysis is also acknowledged. The NMR spec-trometers are part of the National NMR Network (PTNMR) and partially supported by Infrastructure Project N degrees 022161 (co-financed by FEDER through COMPETE 2020, POCI and PORL and FCT through PIDDAC) . A. L. was also supported by FCT through a research contract (http://doi. org/10.54499/DL57/2016/CP1382/CT0007) .