Supervisões em Curso

Projectos

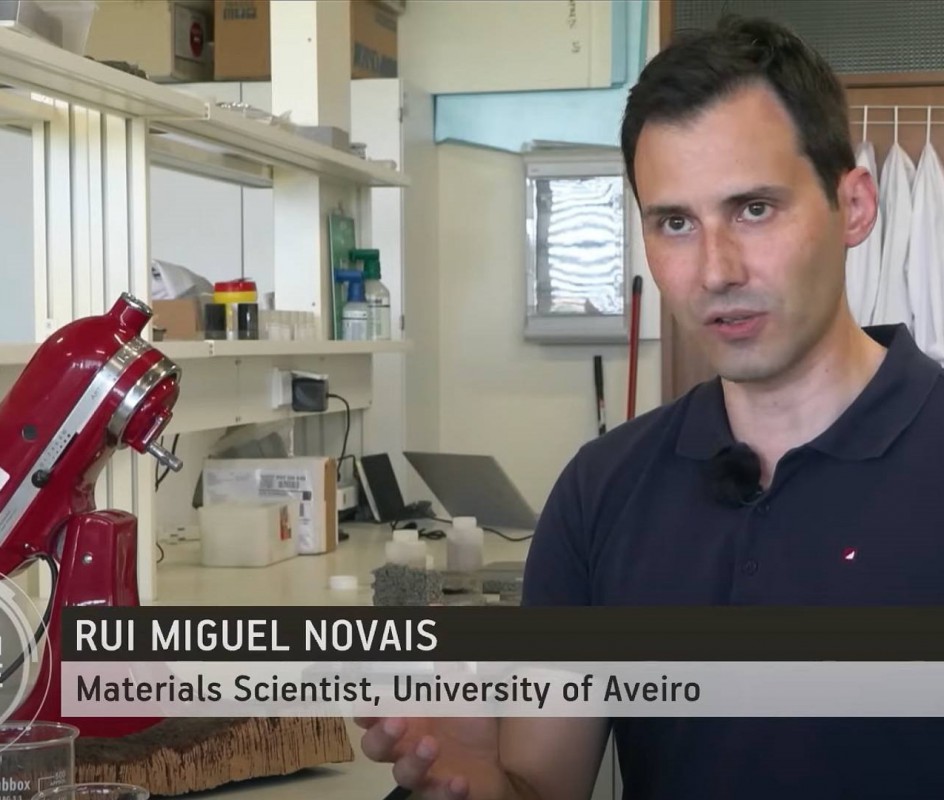

Geopolímeros inteligentes (SMART-G)

Coordenador LocalFundação para a Ciência e a Tecnologia

O projeto visa o desenvolvimento, a produção, e a demostração de componentes leves e resistentes ao fogo para a indústria da construção.Polímeros orgânicos multifuncionais à base de resíduos de bauxite para o tratamento de lixiviados ácidos de minas Portuguesas; (MAXIMUM)

CoordenadorFundação para a Ciência e a Tecnologia

Minas Resíduos Tratamento de águas Economia circularRecycled Waste Materials in Mortars. (RECLAIM)

ParticipanteIndustry National

Publicações

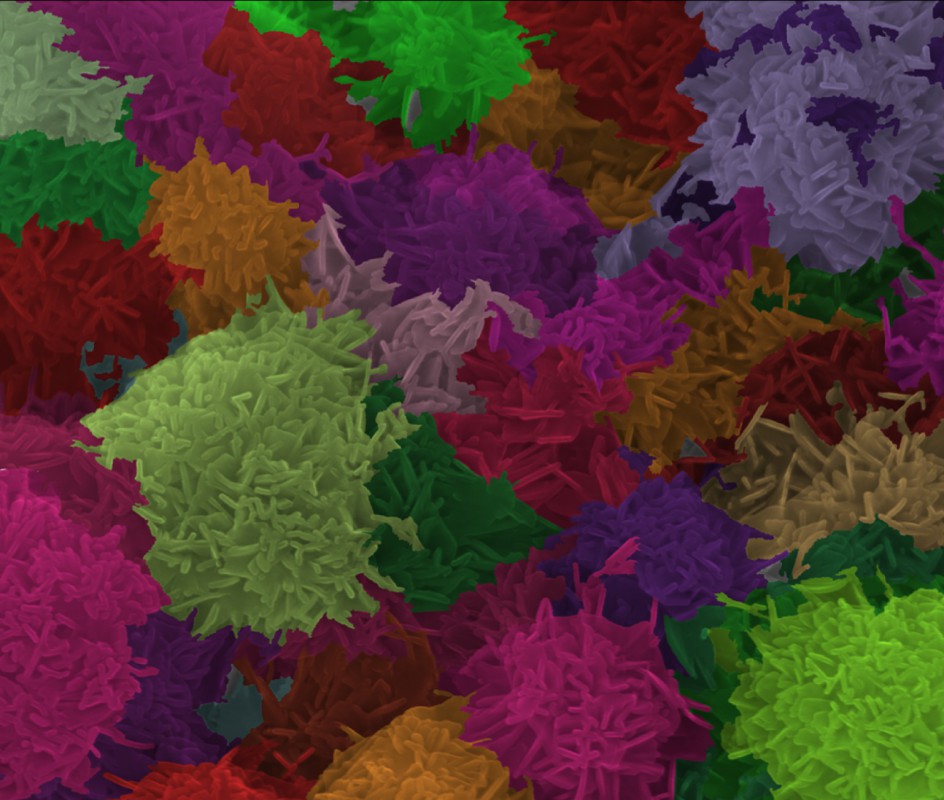

Red mud-based inorganic polymer spheres bulk-type adsorbents and pH regulators

Novais, RM; Carvalheiras, J; Seabra, MP; Pullar, RC; Labrincha, JA

2019, MATERIALS TODAY, 23, 105-106.

ISBN:

1873-4103

Sustainable and efficient cork - inorganic polymer composites: An innovative and eco-friendly approach to produce ultra-lightweight and low thermal conductivity materials

Novais, RM; Senff, L; Carvalheiras, J; Seabra, MP; Pullar, RC; Labrincha, JA

2019, CEMENT & CONCRETE COMPOSITES, 97, 107-117.

ISBN:

1873-393X

Pyrolysed cork-geopolymer composites: A novel and sustainable EMI shielding building material

Novais, RM; Saeli, M; Caetano, APF; Seabra, MP; Labrincha, JA; Surendran, KP; Pullar, RC

2019, CONSTRUCTION AND BUILDING MATERIALS, 229.

ISBN:

1879-0526

Comparison of low and high pressure infiltration regimes on the density and highly porous microstructure of ceria ecoceramics made from sustainable cork templates

Novais, RM; Pullar, RC

2019, JOURNAL OF THE EUROPEAN CERAMIC SOCIETY, 39, 4, 1287-1296.

ISBN:

1873-619X

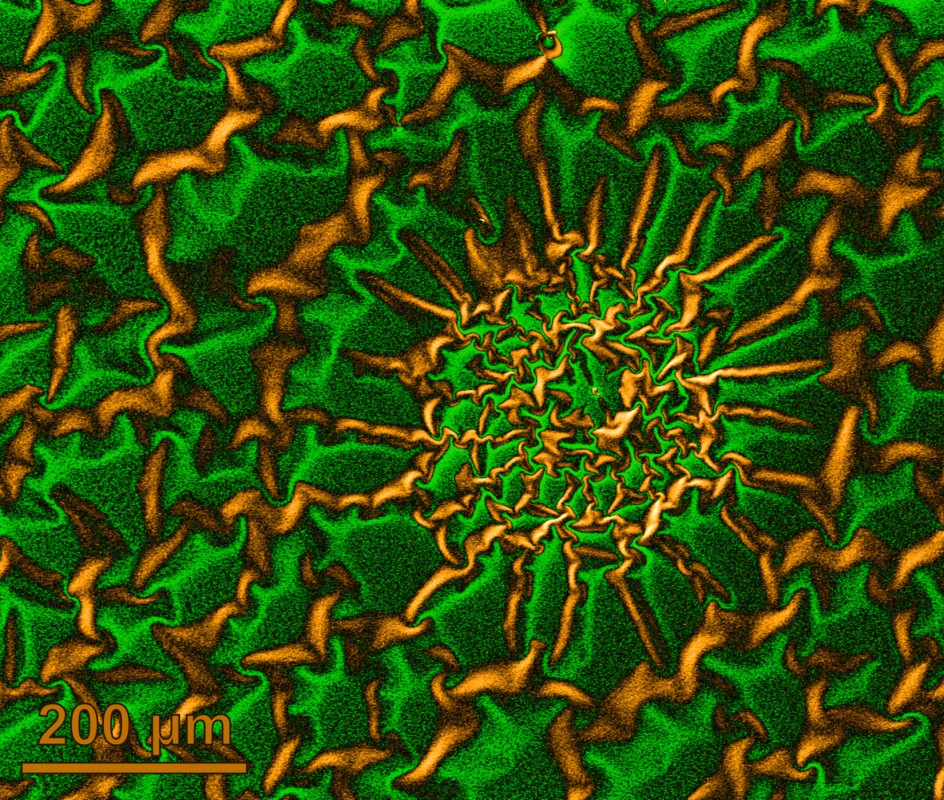

A Review of Solar Thermochemical CO2 Splitting Using Ceria-Based Ceramics With Designed Morphologies and Microstructures

Pullar, RC; Novais, RM; Caetano, ARF; Barreiros, MA; Abanades, S; Oliveira, FAC

2019, FRONTIERS IN CHEMISTRY, 7.

A sustainable multi-function biomorphic material for pollution remediation or UV absorption: Aerosol assisted preparation of highly porous ZnO-based materials from cork templates

Quarta, A; Novais, RM; Bettini, S; Iafisco, M; Pullar, RC; Piccirillo, C

2019, JOURNAL OF ENVIRONMENTAL CHEMICAL ENGINEERING, 7, 2.

ISBN:

2213-3437

Biomass fly ash geopolymer monoliths for effective methylene blue removal from wastewaters

Novais, RM; Ascensao, G; Tobaldi, DM; Seabra, MP; Labrincha, JA

2018, JOURNAL OF CLEANER PRODUCTION, 171, 783-794.

Red mud as a substitute coloring agent for the hematite pigment

Carneiro, J; Tobaldi, DM; Hajjaji, W; Capela, MN; Novais, RM; Seabra, MP; Labrincha, JA

2018, CERAMICS INTERNATIONAL, 44, 4, 4211-4219.

Red mud and electroplating sludge as coloring agents of distinct glazes: The influence of heat treatment

Carneiro, J; Capela, MN; Tobaldi, DM; Novais, RM; Seabra, MP; Labrincha, JA

2018, MATERIALS LETTERS, 223, 166-169.

lInfluence of water and aluminium powder content on the properties of waste-containing geopolymer foams

Novais, RM; Ascensao, G; Ferreira, N; Seabra, MP; Labrincha, JA

2018, CERAMICS INTERNATIONAL, 44, 6, 6242-6249.

Evaluation of the Reactivity of Red Mud-Based Slags for Geopolymers Production

Gameiro, T; Labrincha, J.; Novais, R.M.

2022.

Reusing spent fluid catalytic cracking catalyst as adsorbent in wastewater treatment applications

Gameiro, T; Costa, C.; Labrincha, J.; Novais, R.M.

2022.

Reactivity assessment of red mud-based slags towards geopolymers production

Tânia GAMEIRO, Elise FRANÇOIS, Lukas ARNOUT, Youen DIQUÉLOU, David TOBALDI, Catarina NOVO, Silviana ONISEI, João LABRINCHA, Rui NOVAIS

2022.

pH control in anaerobic bioreactors using fly-ash based geopolymers as buffer material

T. Gameiro, C. Correia, R. Novais, P. Seabra, J. Labrincha, I. Capela

2019.