abstract

Ecopolyol production from acid liquefaction of cork powder was studied for the first time using PEG 400 and glycerol as liquefaction solvents in the presence of sulfuric acid at moderate temperature and atmospheric pressure. The effect of the temperature, concentration of catalyst, and time on the liquefaction yield has been investigated using a fixed set of reaction conditions namely, a liquefaction solvent mixture/cork powder ratio of 5/1 and a solvent mixture PEG 400/glycerol ratio of 90/10. The full-factorial design of experiments (DOE) 23 was applied to obtain an optimized set of liquefaction conditions aiming at minimizing the residue content. The minimum residue contents experimentally obtained in this study were 29 wt %, related to cork powder, which were achieved at 150 C, 4 wt % of sulfuric acid, and 60 min. This value corresponds to 5 wt % of residue per total mass of reaction product. The polyols obtained under optimal conditions present similar characteristics (hydroxyl number value 219 mg(KOH)/g(polyol) and viscosity 2875 cP, at 25 degrees C) to those of petroleum-based polyols typically used in the polyurethane foam industry.

keywords

RIGID POLYURETHANE FOAM; LIQUEFIED WOOD; WHEAT-STRAW; POLYOL; RESIDUES; BIOPOLYOLS; GLYCEROL; LIGNIN

subject category

Chemistry; Science & Technology - Other Topics; Engineering

authors

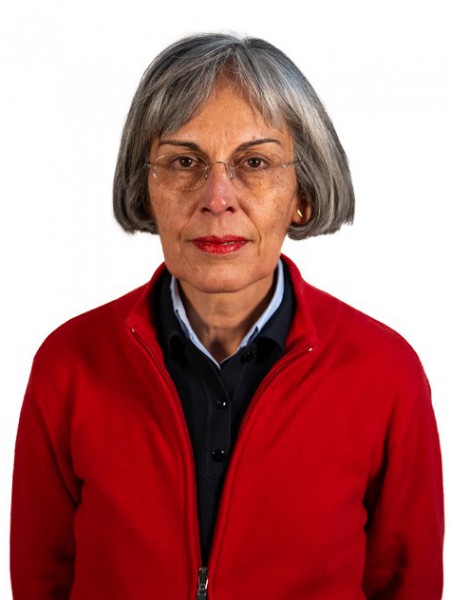

Soares, B; Gama, N; Freire, C; Barros-Timmons, A; Brandao, I; Silva, R; Neto, CP; Ferreira, A

our authors

Projects

acknowledgements

The authors thank QREN/FEDER for funding the Ecopolyols project (No. 11435). Amorim group is gratefully acknowledged for supplying cork powder. CICECO acknowledges FCT for the Pest-C/CTM/LA0011/2013 project. C.F. acknowledges FCT/MCTES for a research contract under the Program