abstract

In this work the preparation of viscoelastic bio-based polyurethane foams (PUFs) using polyols obtained via acid liquefaction of coffee grounds wastes has been optimized. In a first stage, the effect of different ratios of isocyanate content to hydroxyl number (0.6, 0.7 and 0.8) and of three distinct percentages of catalyst (3%, 5% and 7%) on the extent of the polymerization reaction was studied by infrared spectroscopy. Next, different percentages of surfactant (14%, 16% and 18%) and blowing agent (12%, 14% and 16%) were used to assess their effect on the density, thermal conductivity and mechanical properties of the foams, including their recovery time. The mechanical properties of the ensuing foams proved to be very interesting due to their viscoelastic behavior. PUFs were also characterized by scanning electron microscopy (SEM) revealing a typical cellular structure and by thermogravimetric analysis (TGA) which proved that these materials are thermally stable up to 190 degrees C. These results suggest other potential applications for these materials beyond heat insulation in areas where damping properties can be an added value. (C) 2015 Elsevier Ltd. All rights reserved.

keywords

OIL-BASED POLYOL; MECHANICAL-PROPERTIES; COFFEE; LIQUEFACTION; GLYCEROL; LIGNIN; ACID

subject category

Materials Science

authors

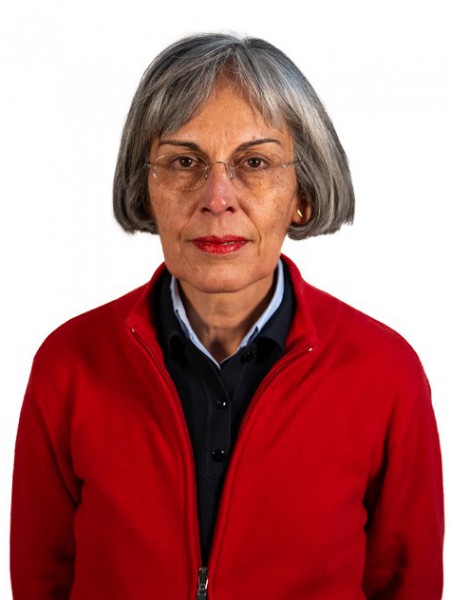

Gama, NV; Soares, B; Freire, CSR; Silva, R; Neto, CP; Barros-Timmons, A; Ferreira, A

our authors

acknowledgements

The authors would like to acknowledge QREN/FEDER for funding the Ecopolyols Project (No 11435). Thermal Analysis Laboratory was funded by FEDER Funds through Programa Operacional Factores de Competitividade - COMPETE and by National Funds through FCT under the Project REEQ/515/CTM/2005. The authors would also like to acknowledge Dow Chemical for kindly supplying of the isocyanate. CICECO acknowledges FCT for the FCOMP-01-0124-FEDER-037271 (PEst-C/CTM/LA0011/2013). C. Freire acknowledges FCT/MCTES for a research contract under the Program