abstract

In this study polyurethane (PU) residues were mixed with residues of textile fibers (cotton, wool and synthetic fibers up to 70 wt/wt) to produce 100% recycled composites. In addition, the effect of the type of fiber on the performance of the ensuing composites was evaluated. The presence of fibers showed similar effect on the density, reducing the density in the 5.5-9.0% range. In a similar manner, the addition of fillers decreased their thermal conductivity. The 70 wt/wt wool composite presented 38.1% lower thermal conductivity when compared to the neat matrix, a reduction that was similar for the other type of fibers. Moreover, the presence of fillers yields stiffer materials, especially in the case of the Wool based composites, which with 70 wt/wt of filler content increased the tensile modulus of the ensuing material 3.4 times. This was attributed to the aspect ratio and stiffness of this type of fiber. Finally, the high-water absorption and lower thermal stability observed, especially in the case of the natural fibers, was associated with the hydrophilic nature of fibers and porosity of composites. Overall, the results suggest that these textile-based composites are suitable for construction and automotive applications, with the advantage of being produced from 100% recycled raw-materials, without compromised performance.

keywords

MECHANICAL-PROPERTIES; WATER-ABSORPTION; POLYPROPYLENE COMPOSITES; DEGRADATION BEHAVIOR; THERMAL-DEGRADATION; MATRIX COMPOSITES; POLYMER; POROSITY; SURFACE; RICINOLEATE

subject category

Materials Science, Composites

authors

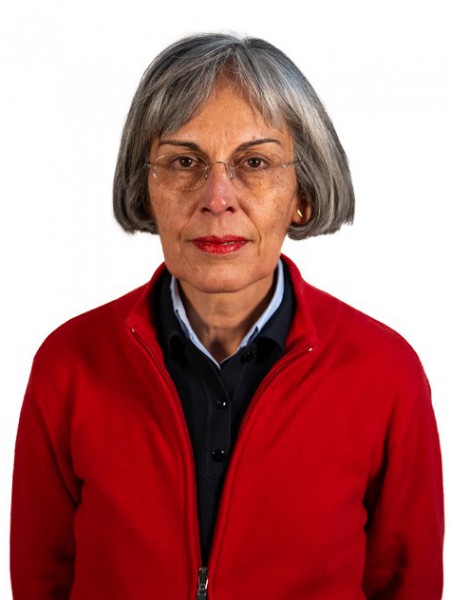

Gama, N; Godinho, B; Barros-Timmons, A; Ferreira, A

our authors

Projects

CICECO - Aveiro Institute of Materials (UIDB/50011/2020)

acknowledgements

The author(s) disclosed receipt of the following financial support for the research, authorship, and/or publication of this article: This work was developed within the scope of the project CICECO-Aveiro Institute of Materials, UIDB/50011/2020 & UIDP/50011/2020, financed by national funds through the Portuguese Foundation for Science and Technology/MCTES and by ERDF Funds through Operational Competitiveness and Internationalization Programme -COMPETE 2020 in the frame of the project FlexiRecover -POCI-01-0247-FEDER-003369.