resumo

Melamine-urea-formaldehyde (MUF) resins are highly effective adhesives for lignocellulosic materials. However, their high stiffness hinders applications where flexibility is desired. In this work, MUF resins were modified with benzoguanamine by partially replacing melamine in two different steps of the synthesis. The purpose was to obtain a less densely crosslinked, and hence more flexible, structure after cure. All modified MUF resins were characterized using gel permeation chromatography (GPC). Results suggest that benzoguanamine and its derivatives were integrated into the polymer structure. FTIR and C-13-NMR analysis confirmed the presence of benzoguanamine in the modified resins. The addition of benzoguanamine to the MUF resin synthesis significantly improved the flexibility of agglomerated cork panels bound with modified resins. The minimum mandrel diameter on which the panels could be bent by 180 without failure decreased from 18 mm to 12 mm diameter, while the remaining key properties of the panels were maintained (tensile strength and boiling water resistance). The formaldehyde content of the panels (determined according to EN120) corresponds to E1 class.

palavras-chave

UREA-FORMALDEHYDE RESINS; WATER

categoria

Engineering; Materials Science

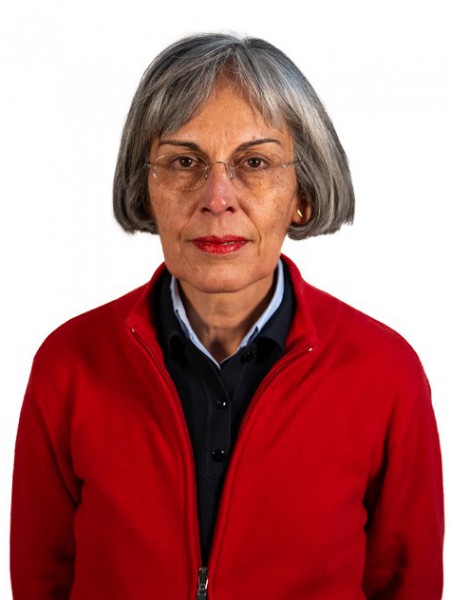

autores

Antunes, A; Duarte, M; Paiva, N; Ferra, J; Martins, J; Carvalho, L; Barros-Timmons, A; Magalhaes, FD

nossos autores

agradecimentos

This work was financially supported by: EuroResinas - Inclustrias Quimicas S.A.; Project 2GAR (SI I&DT - Projects in co-promotion) in the scope of Portugal 2020 co-funded by FEDER (Fundo Europeu de Desenvolvimento Regional) under the framework of POCI (Programa Operacional Competitividade e Internacionalizacao); Project POCI-01-0145-FEDER-006939 (Laboratory for Process Engineering. Environment. Biotechnology and Energy - LEPABE) funded by FEDER funds through COMPETE2020 - Programa Operacional Competitividade e Internacionalizacao (POCI) - and by national funds through FCT - Fundacao para a Ciencia e a Tecnologia; and Project CICECO-Aveiro Institute of Materials. POCI-01-0145-FEDER-007679 (FCT Ref. UID/CTM/50011/2013) financed by national funds through the FCT/MEC and when appropriate co-financed by FEDER under the PT2020 Partnership Agreement. Ana Antunes wishes to thank FCT for PhD grant PD/BDE/113544/2015 and to ENGIQ - Doctoral Programme in Refining. Petrochemical and Chemical Engineering (PDERPQ). Authors wish to thank CEMUP, Porto, for the RMN analysis.