resumo

Adhesives obtained by copolymerizing urea, formaldehyde, and difunctional polyetheramine with different molecular weights (230, 600, 900, and 2000 gmol(-1)) are presented as a more resilient alternative to conventional urea-formaldehyde resins. Urea and polyetheramine contents were varied and the resulting resins characterized by FTIR, C-13-NMR, and TGA. These resins were used for production of agglomerated cork panels, an application that demands that the binder system is flexible. Polyetheramine with molecular weight 900 g mol(-1) yielded the most promising agglomerated cork panel, with remarkable flexibility, good tensile strength, and with the E1 formaldehyde content specification for wood-based panels used in construction, according to European Standard EN 12460-5. These new thermoset adhesives have demonstrated to be capable of being used in systems where conventional formaldehyde-based resins do not perform well due to inherent high rigidity. (C) 2018 Wiley Periodicals, Inc.

palavras-chave

WOOD JOINTS; STRESS; AMINE; FOAM

categoria

Polymer Science

autores

Antunes, A; Rego, M; Paiva, N; Ferra, J; Martins, J; Carvalho, L; Barros-Timmons, A; Magalhaes, FD

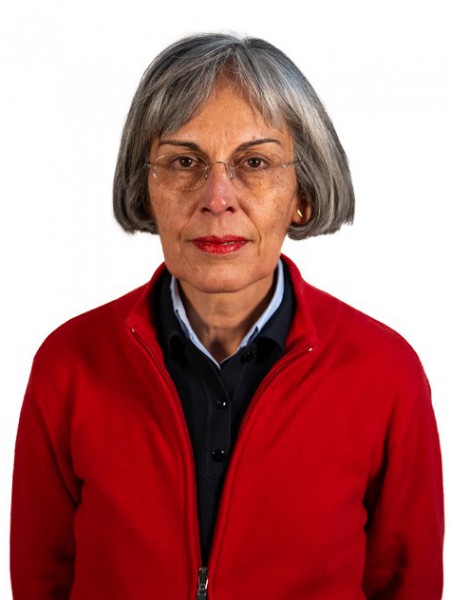

nossos autores

agradecimentos

This work was financially supported by: EuroResinas-Industrias Quimicas S.A.; Project 2GAR (SI I&DT-Projects in co-promotion) in the scope of Portugal 2020 co-funded by FEDER (Fundo Europeu de Desenvolvimento Regional) under the framework of POCI (Programa Operacional Competitividade e Internacionalizacao); Project POCI-01-0145-FEDER-006939 (Laboratory for Process Engineering. Environment. Biotechnology and Energy - LEPABE) funded by FEDER funds through COMPETE2020-Programa Operacional Competitividade e Internacionalizacao (POCI)-and by national funds through FCT-Fundaocaoo para a Ciencia e a Tecnologia; and Project CICECO-Aveiro Institute of Materials. POCI-01-0145-FEDER-007679 (FCT Ref. UID/CTM/50011/2013) financed by national funds through the FCT/MEC and when appropriate co-financed by FEDER under the PT2020 Partnership Agreement. A. A. thanks FCT for Ph.D. grant PD/BDE/113544/2015 and to ENGIQ-Doctoral Programme in Refining, Petrochemical and Chemical Engineering (PDERPQ).