abstract

Urea-formaldehyde resins are successfully used in many contexts, but their tightly crosslinked thermoset structure impairs some applications, due to stiff and brittle behavior. In this work we show that copolymerization of urea and formaldehyde with glycols introduces linear flexible segments in the polymer structure, thus increasing the resilience and flexibility of the resin after curing. Glycols with different molecular weights (106, 200 and 400 g/mol) were incorporated in the synthesis in different amounts. The chemical and physical-mechanical properties of the resulting products were investigated in detail, namely using FTIR, C-13 RMN, GPC/SEC analysis, dynamic mechanical analysis, adhesive bond strength, and tensile-strain testing. Use of polyethyleneglycol with molecular weight 200 g/mol yielded the most promising glycol-urea-formaldehyde resin, with remarkable resilience and good adhesion properties. When used for paper impregnation, the modified resins yielded flexible and tough papers, in comparison with a conventional urea-formaldehyde resin, which produced brittle papers that fractured easily upon bending.

keywords

EMULSION PAINT FORMULATION; COPOLYMER COMPOSITE; IMPREGNATED PAPER; WOOD JOINTS; RESISTANCE; ADHESIVES; EMISSION; STRENGTH; STRESS; ACID

subject category

Polymer Science

authors

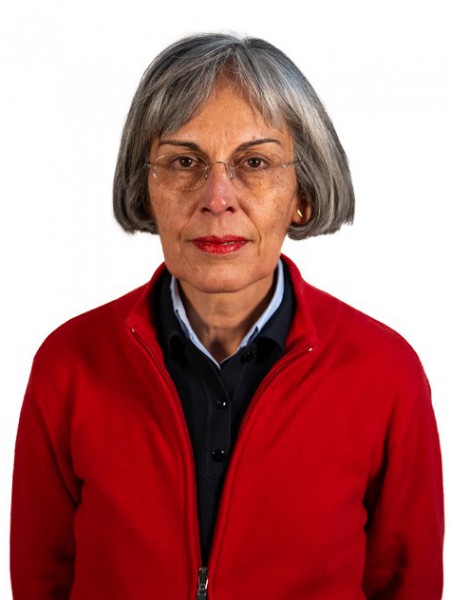

Antunes, A; Paiva, N; Ferra, J; Martins, J; Carvalho, L; Barros-Timmons, A; Magalhaes, FD

our authors

acknowledgements

This work was financially supported by: EuroResinas - Industrias Quimicas S.A.; Project 2GAR (SI I&DT - Projects in co-promotion) in the scope of Portugal 2020 co-funded by FEDER (Fundo Europeu de Desenvolvimento Regional) under the framework of POCI (Programa Operacional Competitividade e Internacionalizacao); Project POCI-01-0145-FEDER-006939 (Laboratory for Process Engineering. Environment. Biotechnology and Energy LEPABE) funded by FEDER funds through COMPETE2020 - Programa Operacional Competitividade e Inteniacionalizacao (POCI) - and by national funds through FCT Fundacao para a Ciencia e a Tecnologia; and Project CICECO-Aveiro Institute of Materials. POCI-01-0145-FEDER-007679 (FCT Ref. UID/CTM /50011/2013) financed by national funds through the FCT/MEC and when appropriate co-financed by FEDER under the PT2020 Partnership Agreement. Ana Antunes wishes to thank FCT for PhD grant PD/BDE/113544/2015 and to ENGIQ Doctoral Programme in Refining. Petrochemical and Chemical Engineering (PDERPQ). The authors acknowledge the collaboration of Margarida Almeida in the ABES tests.