abstract

Additive manufacturing enables the creation of lighter, stronger parts and systems. To improve the 3-dimensional (3D) printed quality of bio-based composites, in this study, bamboo fibers were chemically modified via a two-step reaction. In the first step, NCO groups (of a diisocyanate) were grafted onto the surface of fibers, which were subsequently reacted with a polyol. The chemical modification was confirmed by spectroscopic analysis; the hydrophobicity, density, and thermal degradation of the fibers were also evaluated. Afterward, 3D-printed objects were produced using these fibers. First, the printability of these composites was assessed by analyzing their melting flow index (MFI) and glass transition temperature (T-g) values. Next, the enhancement of the 3D printing quality was confirmed by analyzing the morphology of the 3D-printed specimens. The advantage of using treated fibers was reflected in the improved mechanical performance of the obtained 3D specimens.

keywords

MECHANICAL-PROPERTIES; CELLULOSE FIBERS

subject category

Polymer Science

authors

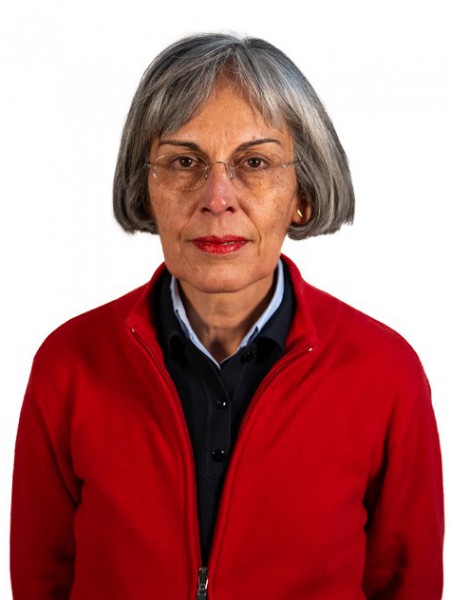

Gama, N; Magina, S; Ferreira, A; Barros-Timmons, A

our authors

acknowledgements

This work was developed within the scope of the project CICECO-Aveiro Institute of Materials, UIDB/50011/2020 and UIDP/50011/2020, financed by national funds through the Portuguese Foundation for Science and Technology/MCTES. Sandra Magina acknowledges FCT for the PhD grant SFRH/BD/121275/2016. The authors acknowledge Martinho Oliveria for the MF measurements.