There are about two million tons of industrial waste produced in Portugal annually and whose fate a group of researchers of CICECO (UA) want to turn into cement. The solution aims not only to end the environmental problem caused by landfills deposition of industrial waste, in which there a life span of tens of thousands of years, but also enhancing the its value as raw material.

Among the industrial waste whose researchers found a way to give a second life, are mostly inorganic, as the ash produced by cellulose industry, debris from quarries and toxic red sludge from aluminum plants. The achieved result is cement with zero toxicity and that meets as well market functionality standards.

"The cement that we have achieved can be used as the existing ones," says João Labrincha. The researcher of the Department of Materials and Ceramic Engineering and CICECO, and research coordinator reveals that the work "replicated the Portland cement compositions, the common hydraulic binder" -the type of cement most used in construction because of its high resistance.

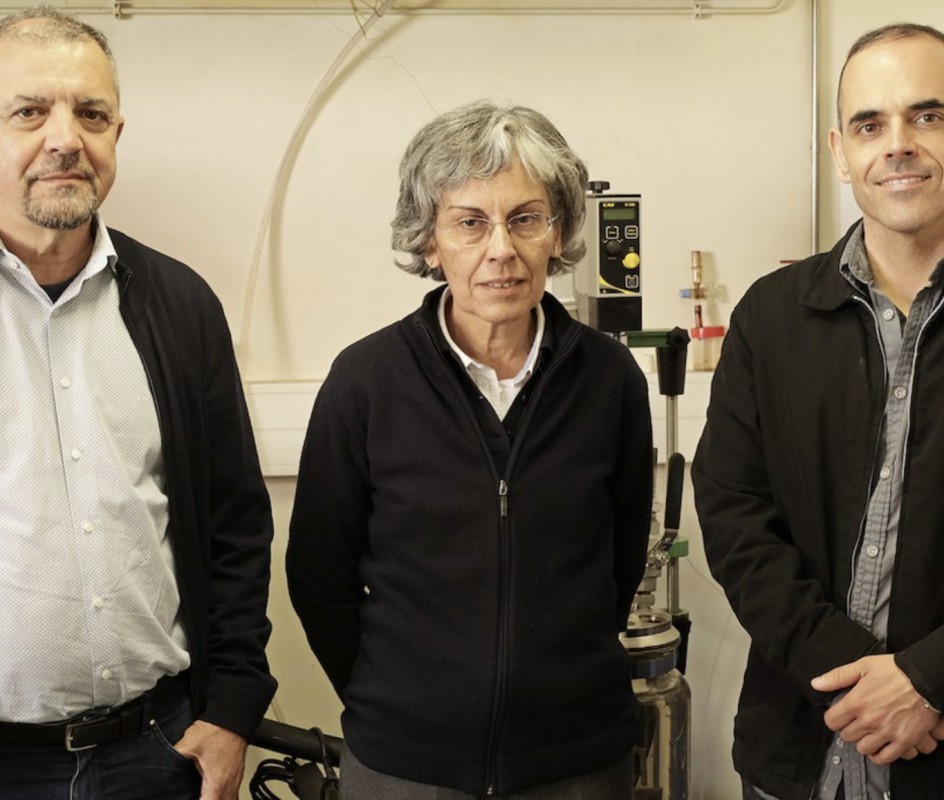

In parallel, and with the same ingredients, researchers João Labrincha, Paula Seabra and Leire Buruberri managed to also make a concrete "based on belite and tricalcium silicate which are constituents of Portland cement," and that is more ecofriendly "because it is baked at a lower temperature [1300 Celsius degrees instead of the 1450 from the ordinary Portland]. As such, this cement is even greener as "saves a considerable amount of energy in the manufacture and reduce carbon dioxide emissions".

The manufacturing process of cement based on industrial waste is very similar to the method already used by industry, but has some secrets and a difference. "The good ground mixture components based on clay and limestone was replaced by waste. This [mix] is then placed directly in an oven and generates, after calcination, a powder called clinker with hydraulic characteristics" says João Labrincha. "This means that it react [hardening] with water, generating solid structures," explains the researcher. As for the organic component, if present in the waste, says João Labrincha, "is completely burned in furnaces and can be transformed into thermal energy."

In a recently published study in the Journal of Hazardous Materials, an international journal in the environmental area, the CICECO team focused on the waste generated by pulp mills. João Labrincha remembers that just one of the Portuguese pulp manufactering business groups, produces over 150 tons of waste per year. This is just a small sample of the amount of industrial waste produced in the country that the team want to see literally climb the walls.

Related Articles

We use cookies for marketing activities and to offer you a better experience. By clicking “Accept Cookies” you agree with our cookie policy. Read about how we use cookies by clicking "Privacy and Cookie Policy".