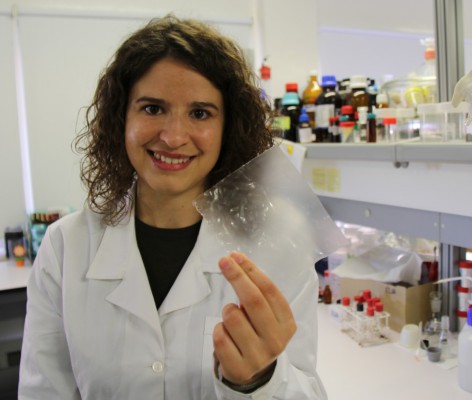

At first glance, food packaging developed by the researcher Idalina Gonçalves at the University of Aveiro (UA) are like any other the plastic commonly used by the food industry and supermarkets. But any resemblance to the materials synthesized from petroleum derivatives it is only in the appearance. Developed exclusively from potato industry residues (such as potato peel and wash water), the bioplastic for packaging foods aims to be an effective alternative to synthetic plastic. In addition to being biodegradable, the compounds of the new bioplastic promote a enhance food preservation when compared with traditional plastics.

Produced using starch, a carbohydrate present in potatoes and whose properties allow to obtain clear films that are also resistant to breakage, odorless and tasteless. The tests already carried out with this packaging material, produced this collaborative work between the departments of Chemistry and Materials and Ceramic Engineering, in QOPNA and CICECO and research units under the supervision of Manuel A. Coimbra and Paula Ferreira, respectively, suggest that work as an effective barrier for food application.

"The inherent biodegradability to the starch packaging is a great advantage over plastic," says Idalina Gonçalves, who notes that the "considerable increase in the last 20 years of synthetic packaging [plastic] has aggravating the waste disposal problem."

"Starch films lose more than 90 percent of their weight after 31 days of incubation on an organic system, while a simple plastic bag can take hundreds of years to be degraded," says the researcher. Moreover, she adds, "the good barrier properties, particularly oxygen and water vapor, of the starch films are also an added value compared to synthetic materials."

Smart packaging

But the work of the team will not stop here. Researchers want to add more properties to the potato plastic. "We will develop films capable of monitoring, for example, oxygen absorption, of carbon dioxide release and moisture content, indicators of fresh food deterioration".

Furthermore, the research team will also want to increase the food shelf life by incorporating extracted active compounds of potato peel, such as cutin, for the barrier properties and mechanical strength and polyphenols, for antimicrobial and antioxidant properties.

In the laboratory the researchers are prepared to add, to the already developed films, compounds capable of detecting the deterioration of food, humidity and temperature. "One of our goals is, for example, develop colorimetric materials that respond to changes in physical and chemical properties of food [as indicators of time, temperature, pH or freshness], allowing the consumer to an assessment of the quality of their food," reveals the researchers.

Huge food surplus to take advantage

Today, the potato is the fourth largest crop in the world and is a food culture in constant growth. However, its overproduction is causing a collapse in the price of potatoes in almost all European countries. For example, in Portugal, the researchers point out, "the average price for potatoes is as high as 5 cents per kilogram, which represents a value well below the production cost."

Moreover, the potato processing industry also generates plenty of by-products resulting from the manufacture of food products made from potatoes such as peel (6-10 percent) and other residues resulting from the cutting and removal of defects (15 a percent). In addition, whole potatoes that are not intended for human consumption are also wasted.

Near the industrial market

"This flow of by-products is a significant effort in waste management, which compromises the sustainability of potato processing industries. The valuation of its by-products arises then as a research focus, "whose team has been involved, precisely, in the development of materials from the potato chips industry by-products, with the main target the packaging of fresh foods.

"The use of by-products of the potato chips industry in the development of intelligent packaging will be in a not distant future, a way to promote the conservation of food and the extension of its lifespan, minimizing our ecological footprint," according to researcher that it hopes that within three years the prototype may leave the laboratory scale to the industrial application.

Related Articles

We use cookies for marketing activities and to offer you a better experience. By clicking “Accept Cookies” you agree with our cookie policy. Read about how we use cookies by clicking "Privacy and Cookie Policy".