It is one the most environmentally friendly cement in the world. In addition to be composed mainly from pulp mills waste that would otherwise go to landfills, the production of the 'green' cement developed at CICECO / University of Aveiro, drastically reduces the use of natural resources and can be produced at room temperature, reducing energy consumption. The result is eco-cement to build a more sustainable world.

Developed to have the same characteristics of common cement, better known as Portland cement and whose production is highly polluting, the eco-cement developed in the Department of Materials Engineering and Ceramics is assumed as an alternative to traditional binders.

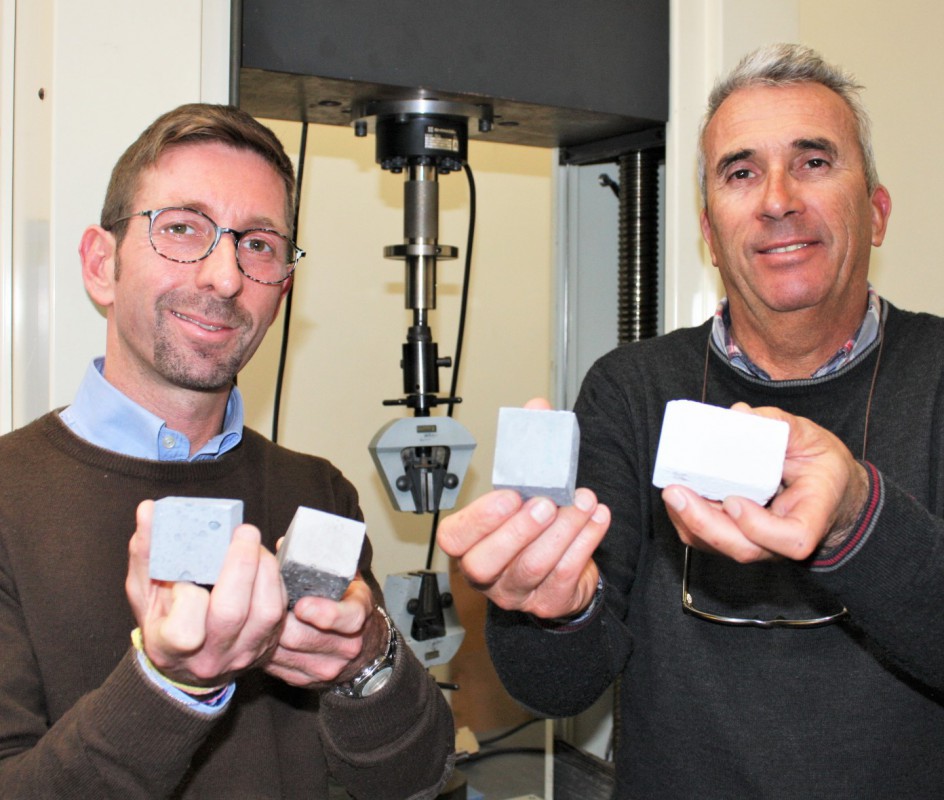

"Our geopolymer mortars are a valid alternative to those produced with Portland cement because they have properties that make them suitable for several applications in construction," explains Manfredi Saeli, the researcher who along with Rui Novais, Paula Seabra and João Labrincha developed the new material.

In fact, adds the researcher, "the materials produced are highly sustainable, less polluting and their production is profitable." In addition, "geopolymers harden quickly, exhibit a stable and uniform matrix, adequate mechanical performance and excellent chemical resistance and aging".

Developed using waste from the pulp industry, namely ash and lime grains that would otherwise be sent to landfill, make up 70 percent of the eco-cement ingredients (the other 30 percent are metakaolin), this new material can be used as a valid and sustainable alternative to Portland cement with identical performance levels.

Related Articles

We use cookies for marketing activities and to offer you a better experience. By clicking “Accept Cookies” you agree with our cookie policy. Read about how we use cookies by clicking "Privacy and Cookie Policy".