abstract

Even though the production of 3D printed foams has already been widely studied, the main focus of the reports has been on their mechanical properties or their cushion behavior. In the present work a preliminary approach is made concerning the potential application of 3D printed PU foams for thermal applications with enhanced mechanical properties. For that propose, cork was used to enhance the properties of the resulting 3D printed composite foams. From the results obtained, it was observed that the addition of cork decreased the density and thermal conductivity of the ensuing foams. The stiffness of the ensuing composites was also reduced. Yet, the use of cork did not affect the thermal stability of the composites. Finally, the layer-to-layer bonding was evaluated and the results suggest that the addition of cork may not jeopardize the performance of the 3D printed PU foams. Besides their thermal insulation properties, the elastomeric behavior of the 3D printed foams produced may find applications that combine thermal insulation with damping properties. Furthermore, advances in the 3D printing technology may increase the range of applications of these foams. (c) 2019 The Authors. Published by Elsevier Ltd. This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/).

keywords

POLYURETHANE FOAMS; MECHANICAL-PROPERTIES; PHYSICAL-PROPERTIES; CRUDE GLYCEROL; THERMAL-CONDUCTIVITY; CORK; DIFFUSIVITY; ABSORPTION

subject category

Materials Science

authors

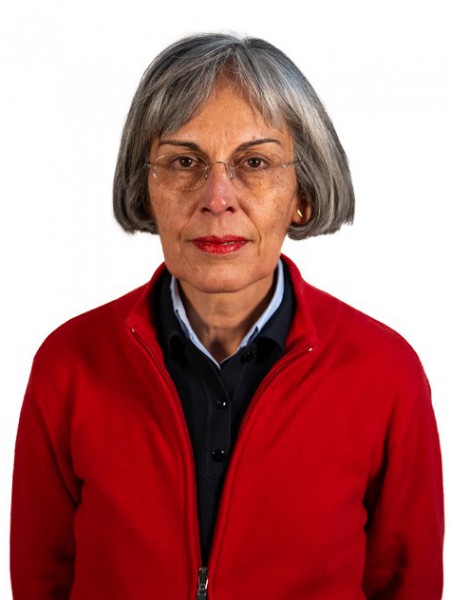

Gama, N; Ferreira, A; Barros-Timmons, A

our authors

acknowledgements

This work was developed within the scope of the project CICECO-Aveiro Institute of Materials, FCT Ref. UID/CTM/50011/2019, financed by national funds through the FCT/MCTES. The authors would also like to acknowledge Luis Fernandes for the sketch of foam, COMPOGAL - Industria de polimeros, S.A. and Corticeira Amorim, S.A for the TPU and cork, respectively. The authors would also like to acknowledge Jose Martinho Marques de Oliveira for the MFI measurements.