abstract

The reation to fire of polyurethane foams (PUFs) has been a subject of increasing relevance, so in this study the reaction to fire performance of PUFs derived from crude glycerol (CG) has been improved using expanded graphite (EG). The influence of different loadings of EG on the physical mechanical properties of composite foams has been assessed and the results obtained show that it has significant positive impact. Moreover, the reaction to fire of the PUF and EG/PUF composites has been investigated and the results obtained showed that the fire behavior of composite foams containing as little as 5 wt% of EG are significantly improved. Indeed a dramatic reduction of the rate of heat release, mass loss rate, effective heat of combustion and specific extinction area, has been observed even for a relative low amount of EG. Likewise, the use of Infrared Thermography as a function of time has proven that, when EG is used, the combustion stops suddenly and the temperature drops sharply compared with the behavior of the unfilled PUF sample, which suggests that EG acts like a flame extinguisher. The results obtained have proven the suitability of CG for the production of PUFs and that the addition of EG considerably improves the reaction to fire of composite foams.

keywords

OIL-BASED POLYOL; FLAME-RETARDANT; THERMAL-STABILITY; PERFORMANCE; BEHAVIOR; MORPHOLOGY

subject category

Materials Science; Polymer Science

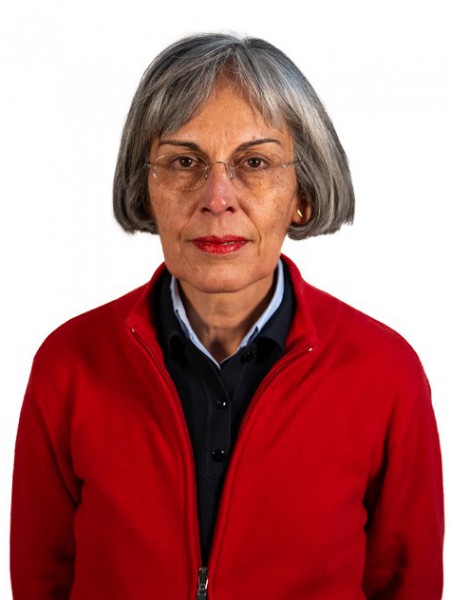

authors

Gama, NV; Silva, R; Mohseni, F; Davarpanah, A; Amaral, VS; Ferreira, A; Barros-Timmons, A

our authors

Groups

G1 - Porous Materials and Nanosystems

G2 - Photonic, Electronic and Magnetic Materials

G4 - Renewable Materials and Circular Economy

acknowledgements

This work was developed within the scope of the project CICECO-Aveiro Institute of Materials, POCI-01-0145-FEDER-007679 (FCT Ref. UID/CTM/50011/2013), financed by national funds through the FCT/ MEC and when appropriate co-financed by FEDER under the PT2020 Partnership Agreement. The project HEAT@UA RECI/CTM-CER/0336/ 2012 is acknowledge for the thermographic and thermal conductivity analyses. The authors would also like to acknowledge Bioportdiesel and Dow Chemical for kindly supplying crude glycerol and isocyanate, respectively.