Abstract

The present invention relates to obtaining a recycled ceramic formulation to produce extruded floor/coating by combining ceramic sludges, glass cullet and aluminum anodizing sludges.

Careful separation process of impurities and of treating glass and anodizing wastes, and use of ceramic sludges properly handled and reasonably pure (e.g., from sanitaryware or tableware products) allows obtaining materials with controlled composition and particle size.

These wastes are at the moment used as raw material in the ceramic industry.

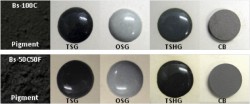

Various combinations of non-hazardous residues were tested to values (by weight) of 40-60% of ceramic sludge + 20-30% of cullet + 20-30% of anodizing sludge. The mixture was carried out in the mill with the addition of plastic clay (up to 15%) when necessary.

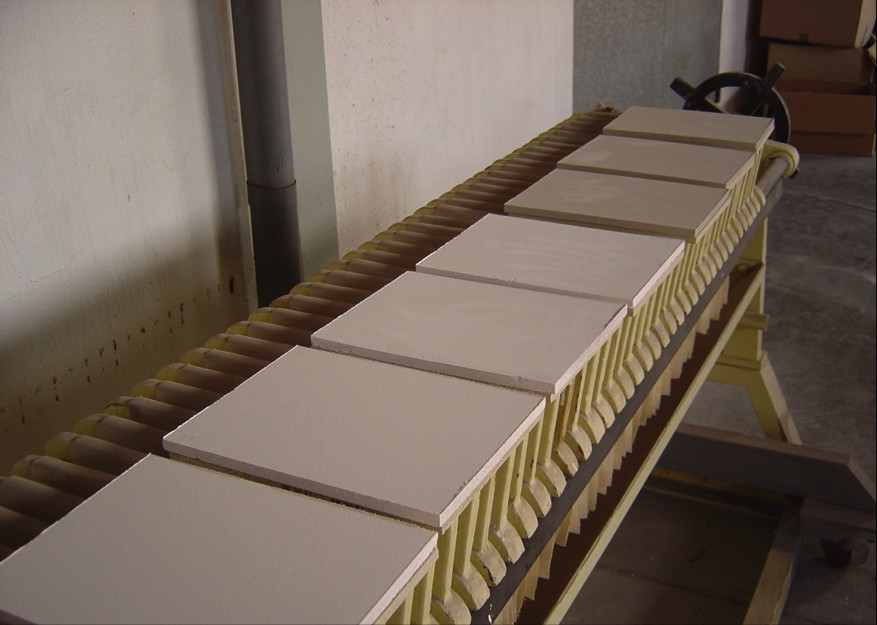

The firing was conducted at different temperatures (1035-1210 ºC) obtaining samples with physical characteristics compatible with porous coatings (up to 1100 °C) and vitrified floor.

Innovative aspects & main advantages

The present invention relates to a new way to obtain a fully recycled ceramic formulation to produce extruded tiles by combining ceramic sludges, glass cullet and aluminum anodizing sludge. The main advantage of this formulation is the reuse of by-products and wastes that would otherwise go to landfill. At the same time, production costs of the extruded ceramic tiles are reduced.

Applications

The main application of this type of work (the potential commercial/industrial sectors) will involve, in general, floor tiles producers and, in particular, those in which the process is done by extrusion.