Abstract

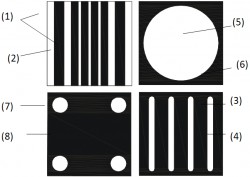

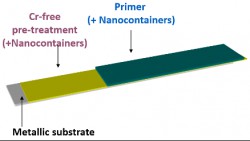

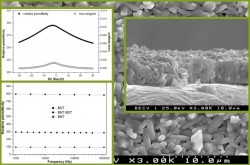

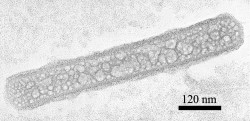

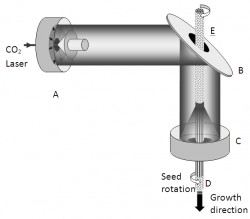

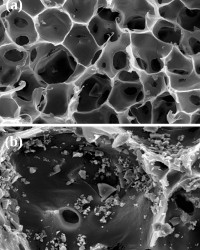

Manufacturing process of NTC (negative temperature coefficient) flat thermistors consisting of diamond films deposited on sintered ceramic substrates. These devices comprise a temperature sensitive diamond surface on one side of the substrate and metallic carbide ohmic contacts on the other. The process has the advantage of using a single deposition technique for producing temperature sensitive diamond surface and ohmic contacts. The new diamond thermistors can be used for temperature measurement in hostile environments, extreme heat or biological mediums. The substrate ensures excellent diamond film adhesion and high mechanical resistance. The thermistor flat geometry maximizes the contact area between the temperature sensitive surface and any solid flat surface on which it is placed. Better response times are achieved when compared with traditional round shape of most of the commercial thermistors.

Innovative aspects & main advantages

The new diamond thermistors can be used for temperature measurements in harsh environments such as aggressive chemicals at high temperature or in biological media due to their inertness. Furthermore, the sintered ceramic substrate guarantees superior adhesion and resistance to fracture under high mechanical loads. The fabricated temperature sensitive diamond surface comprises well adhered ohmic contacts deposited on the backside of the dielectric ceramic substrate. This configuration prevents interaction between the temperature sensitive surface and the surrounding environment which is essential for biochemical devices applications.

Furthermore, the planar geometry of the disclosed thermistor maximizes the contact region between the temperature sensitive surface and any solid flat surface on which it is placed. In this way, improved response times are obtained comparing to traditional round shaped thermistors.

Additional advantages of its use are an:

Improved response times are obtained comparing to traditional round shaped thermistors;

Maximization of the contact region between the temperature sensitive surface and any solid flat surface on which it is placed;

Prevention of the interaction between the temperature sensitive surface and the surrounding environment;

Superior adhesion and resistance to fracture under high mechanical loads.

Applications

The planar diamond thermistors disclosed in this invention are particularly applied but not limited to temperature measurements in combustion and jet engines for the automobile and aerospace industry, respectively; lasers, fuel cells and in biological and aggressive chemical environments.