Abstract

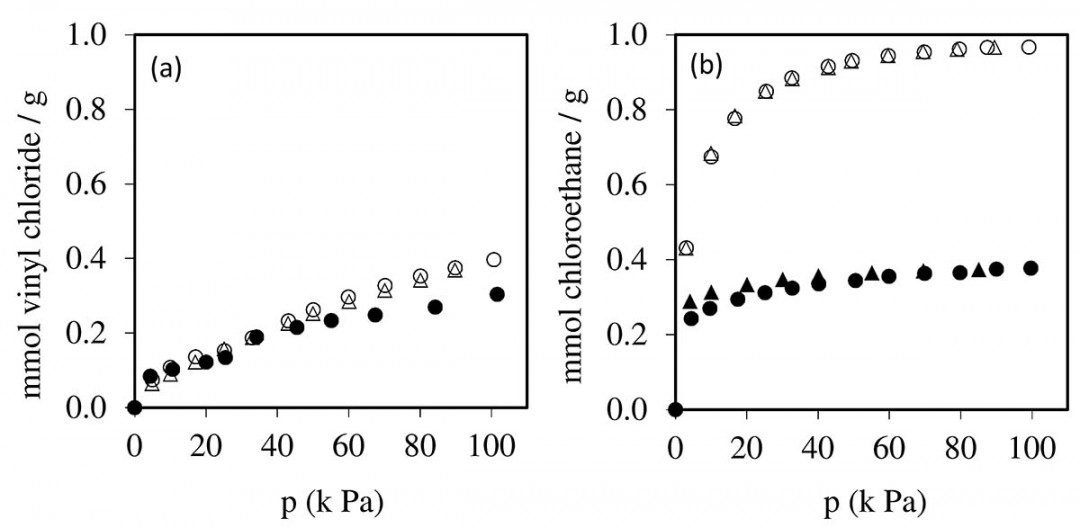

The present invention relates to the separation of ethyl chloride and vinyl chloride by absorption using a crystalline microporous aluminium metilphosphate as the absorbent.

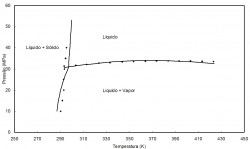

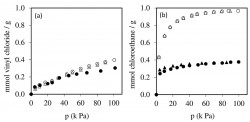

The absorption ability of aluminium methylphosphonate to ethyl chloride is always higher than to vinyl chloride, at the same temperature and in the pressure range of 0 to 100 kPa, the difference increases with the temperature increasing between 20 and 90 °C, thus allowing selective removal of ethyl chloride from a rich stream of vinyl chloride, in which it constitutes an impurity.

Innovative aspects & main advantages

Polyvinyl chloride (PVC) is produced by polymerization of vinyl chloride. The unreacted monomer may be recovered by condensation. However, chloroethane and chloromethane are contaminants present in the vinyl chloride stream, which inhibit the polymerization reaction even when present in minor amounts. Hence, this effluent stream is incinerated at the expense of the unproductive use of the monomer and the costly incineration process which requires the subsequent elimination of HCl formed in the combustion of the effluent gas. requires the subsequent elimination of HCl formed in the combustion of the effluent gas.

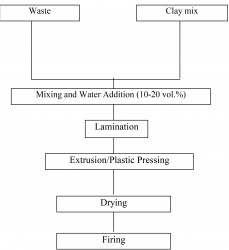

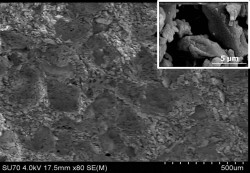

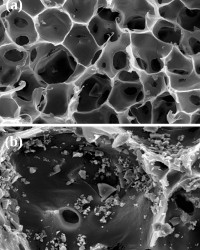

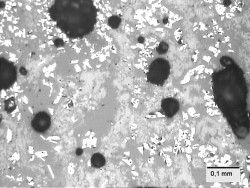

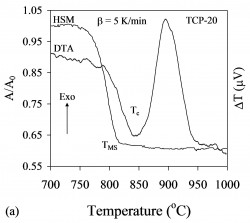

This invention concerns the recovery of vinyl chloride by adsorption of the impurities on a crystalline microporous adsorbent known as aluminum methylphosphonate AlMepO-α or AlMepO-β. The loading capacity of these types of materials is always higher for chloroethane than for vinyl chloride, at the same temperature in the pressure range 0 to 100 k Pa. The difference between the loading capacities increases with increasing temperature between 20 and 90 ºC, allowing for the selective removal of chloroethane present as a contaminant in a stream of concentrated vinyl chloride.

When conventional hydrophilic adsorbents such as activated alumina, silica gel, zeolites are used for the separation of gas mixtures composed of a product of the type CH3CH2R and the corresponding olefin, CH2=CH2R, in which R is a halogen, hydrogen or an alkyl group of low molecular weight, it is generally observed the selective adsorption of the olefin. This invention describes the first adsorbent which adsorbs preferentially the saturated compound which is a contaminant present in streams of olefins of the type CH2=CHR described.

Applications

This type of adsorbent can be used for the separation of gas mixtures of the type CH3CH2R/CH2=CHR, which are commercially important, such as, vinyl chloride/chloroethane, ethyl fluoride/vinyl fluoride, ethyl fluoride/vinyl chloride, ethane/ethylene, propane/propylene e isobutane/isobutene, etc.

The present invention serves the industry that produces PVC. It accounts for a better VOC emission control by minimizing the effluent gas and, simultaneously, the profitable recovery of the raw material from the effluent gas. In Portugal, CIRES – Companhia Industrial de Resinas Sintéticas S.A., is the only company that produces PVC. Internationally, PVC is one of the most important industrial polymers and is produced by Solvay, BASF, Oxychem, Westlake, EVC, Advent, Geon, Aiscondel e Hydro Polymers.