Abstract

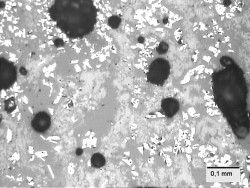

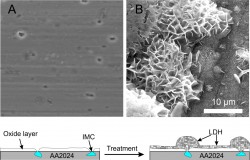

The present invention relates to the manufacture of red clay ceramic products, containing sludge from treatment of effluents generated in metal surface treatment operations.

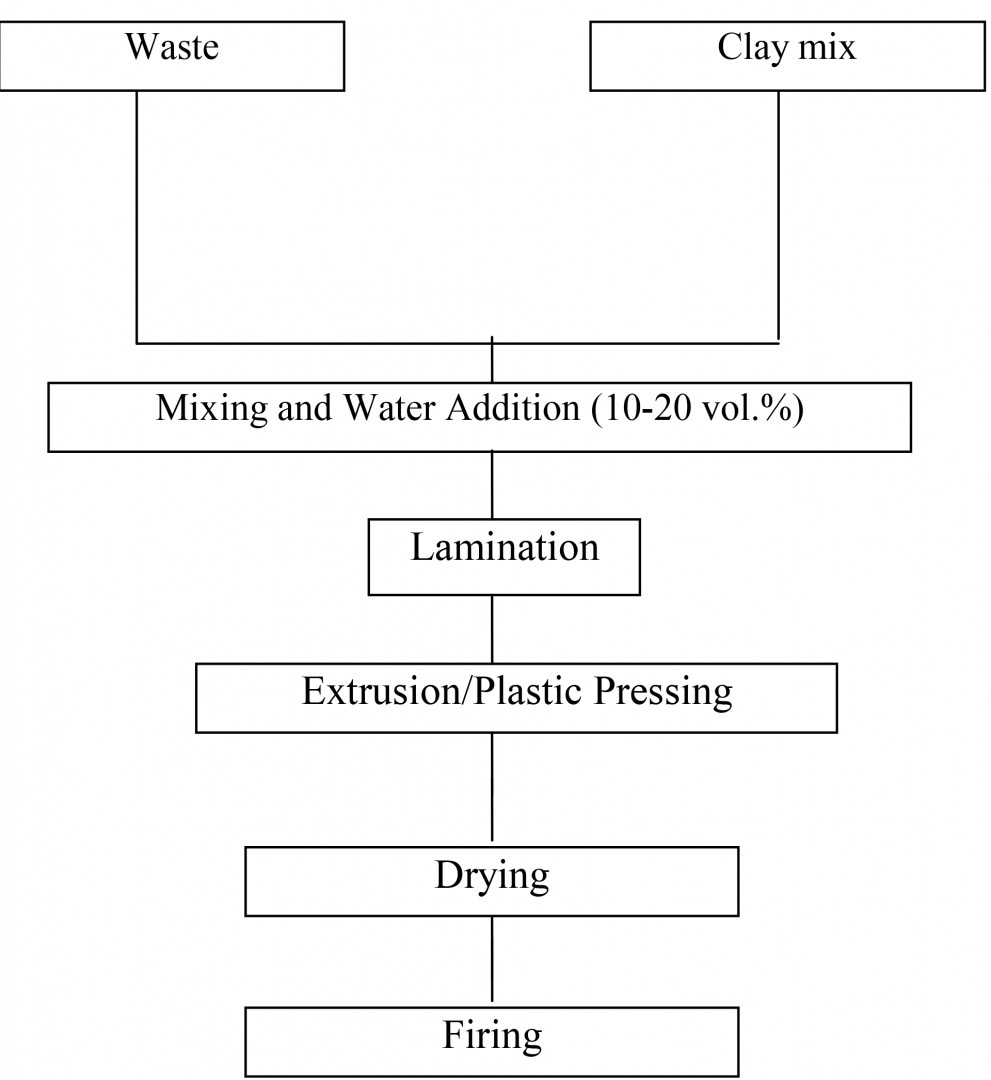

The optimization of the processing conditions, particularly the mixing of sludge with the clay matrix, had by reference the minimum deviation from the normal manufacturing process of ceramic products.

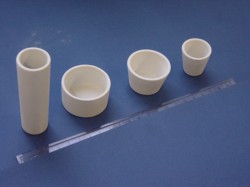

It is possible to incorporate slurry up to 5% by weight, in formulations used to produce bricks, tiles or vaults. The physical characteristics of the fired products are compatible with the requirements of use, in particular, the flexural strength (> 100 kg-f / cm2) and water absorption levels below 10%.

The inertness of the fired products was confirmed by eco-toxicity testing, based on aqueous leaching, according to DIN 38414-S4. With the manufacturing conditions described in this invention, we obtain products that are classified as inert in accordance with Community legislation, in particular for the purpose of landfilling, as stipulated in Directive 31/1999/EC.

Innovative aspects & main advantages

The present invention relates to the manufacture of common red-clay based ceramic products, containing sludge from treatment of effluents generated in metal surface finishing (e.g. plating) industrial operations. The optimization of the processing conditions, particularly the mixing of sludge with the clay matrix, aimed to minimize the deviation from the normal manufacturing conditions and not damage the product properties. It is possible to incorporate up to 5wt% slurry in common formulations used to produce bricks and tiles. The physical characteristics of the fired products are compatible with the requirements of use, in particular the flexural strength (> 10 MPa) and water absorption levels (below 10wt%). The hazardous inertness of the fired products was confirmed by testing their eco-toxicity, based on aqueous leaching performed according to DIN 38414-S4 protocol. With the manufacturing conditions described in this invention, we obtain products that are classified as inert in accordance EU Directive 31/1999.

Applications

The main application of this invention (the potential commercial/industrial sectors) is focused on the producers of sludge, as an alternative to landfill that might be costly (some wastes are dangerous) and to ceramic producers, namely bricks and tiles for common applications (building construction).

Inventors

Batista, João; Silva, Rui; Castro, Fernando; Figueiredo, JoséOur Inventors

Applicant

TecminhoUniversidade do Minho

Universidade de Aveiro

C.F. Duarte &

Filhos, Lda

Alumínios Ibérica, Lda

Fábrica de Serração E Cerâmica Amaro de Macedo, Lda

Ferespe-Fundição de Ferro E Aço, Lda