Abstract

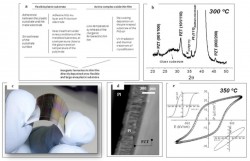

The present invention relates to the production of ceramic materials by using (25-100%) bottom ash obtained from the incineration of solid waste (SW), preferably municipal solid waste (MSW), having application in the construction industry and/or as utility ceramics. While in the manufacture of conventional ceramics for the same applications, clay, quartz and feldspar minerals are the generally used base raw materials, with specific processing functions, in this case, an innovation is that the raw materials can be bottom ash from SW incineration, preferably fully consisting of MSW bottom ash, without the necessity of using any other additive.

Innovative aspects & main advantages

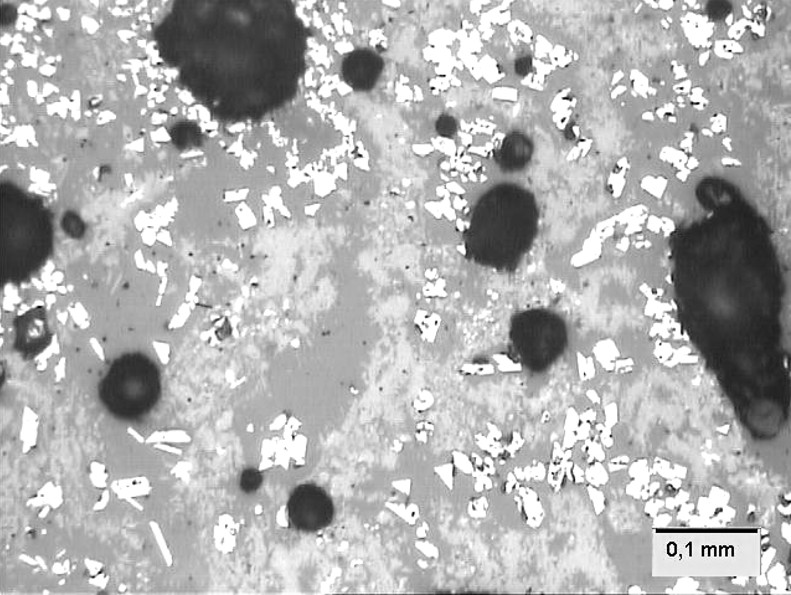

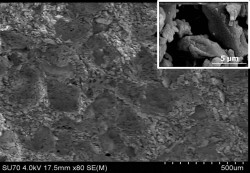

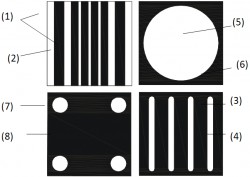

This technology offers an innovative solution with the production of ceramic materials out of bottom ash, resulting from municipal solid waste (MSW) incineration, which can be applied in the construction industry, particularly in floor and wall tiles. The production of these ceramic materials is strictly controlled. Due to a strong aggregation of the particles, an adequately dense ceramic with a granular texture is obtained, which is esthetically attractive and has adequate physical properties and mechanical resistance, to use as construction material. Besides the economic advantages, the environmental gains are also relevant, as regards the recycling of a waste normally disposed in landfills, as well as, the preservation of scarce mineral natural sources.

Applications

This solution has applications in floor and wall tiles, bricks and tiles, decorative and utilitarian ceramic and mosaics manufacturing.