Abstract

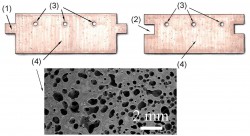

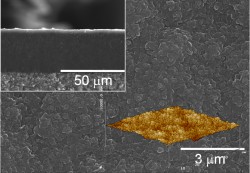

The present invention relates to deposition, by screen-printing, of oxides layers such as TiO2 and ZnO on glazed ceramic pieces, to promote organic dyes degradation by photocatalysis in an aqueous medium. Deposition conditions optimization and subsequent heat treatment of the obtained layers, as well as the oxide/dye concentrations ratio, promotes colored solutions efficient photobleaching. Photodegradation rate is related to the deposited oxide layer thickness, to the surface area and morphology, to the thermal treatment temperature and to the pH of the medium, which are experimental parameters easily adjusted. In optimal conditions, a high degradation rate (90% colour removal after 7 hours) with layers of 50g/m2 consolidated at 750-950 ºC is obtained. Photocatalytic process is stimulated by sunlight or by a lamp emitting in the visible region (400-600 nm).

Innovative aspects & main advantages

The present invention relates to the deposition, by screen-printing, of TiO2 and ZnO layers on glazed ceramic pieces, then able to degrade organic dyes in aqueous medium by photocatalytic action. The optimization of deposition conditions and subsequent heat treatment of the obtained layers is crucial to promote efficient photobleaching of the colored solutions. The photodegradation rate is related to the thickness of the deposited oxide layer, its morphology and surface area. In optimal conditions, high degradation rates (90% discoloration after 7 hours irradiation) are obtained with layers of 50g/m2 consolidated at 750-950 ºC. The photocatalytic process occurs under the sunlight or by exposure to a lamp that emits in the visible region (400-600 nm).

Applications

The industrial applicability is here focused in the manufacturing of ceramic tiles showing novel functionalities. Their use will cover environmental decontamination/remediation actions assured by functional construction materials.