Abstract

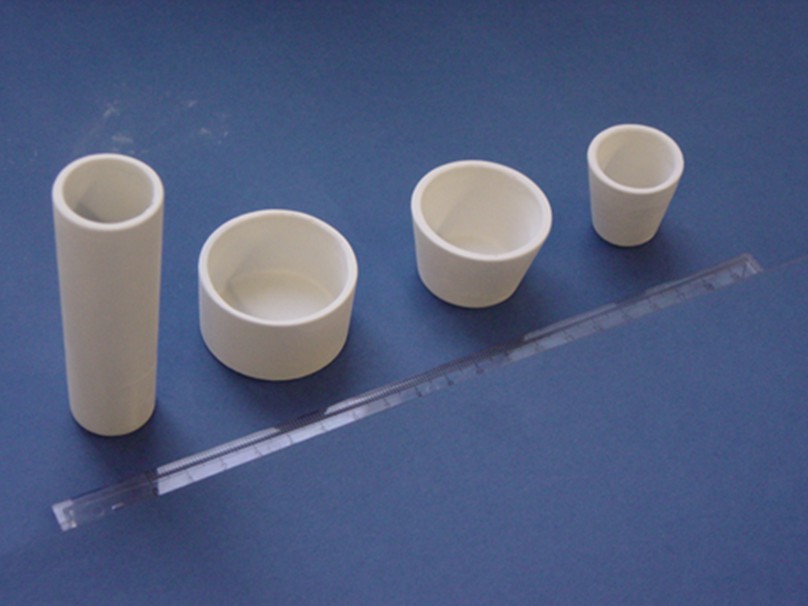

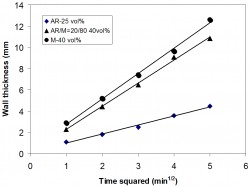

The present invention relates to methods of passivating the surface of aluminium nitride (AlN) particles against hydrolysis reactions that occur spontaneously when this material is placed in contact with water in the vapour state and, especially in liquid state, as well as to a method of preparation stable and highly concentrated AlN based aqueous suspensions with formulations and rheological properties suitable for fabricating bulky ceramic bodies or substrates by colloidal shaping techniques, or to powder granulation processes by spray drying or freeze drying, to obtain granules with excellent properties for dry pressing technologies.

Innovative aspects & main advantages

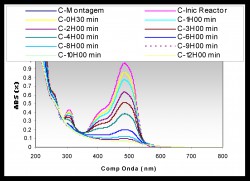

Aluminium nitride is usually processed in non-aqueous environments because it is very sensitive to water molecules. But organic media raise serious concerns related to health and safety of the workers, and environmental and economic. Attempts have been made to overcome these drawbacks by protecting the surface of AlN particles with hydrophobic substances to enable dispersing them in water.

The passivation method proposed uses hydrophilic substances to prevent hydrolysis reactions that occur spontaneously when AlN powder particles enter in contact with water. This enable the preparation of stable and highly concentrated aqueous suspensions based on AIN, suitable for consolidating advanced ceramics by colloidal shaping techniques and the production of homogeneous granules for dry pressing technologies by spray drying or freeze drying.

Applications

Aluminium nitride is the most important high thermal conductivity ceramic material. It is therefore regarded with much interest for application where this property is essential (substrates for microelectronic applications, heat exchange related applications such as high speed trains, etc.).