Abstract

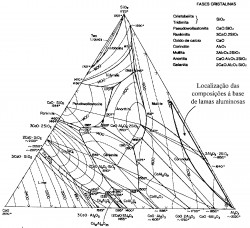

The present invention relates to a method for enabling the manufacture of stoneware ceramics by slip casting from clay rich sedimentary rocks comprising very fine kaolinite-based particles and other minerals from the group of smectites (bentonite, illite, montmorillonite) and the group of paligorskites and sepiolites.

The presence of these clay minerals causes the formation of highly viscous and thixotropic suspensions making them impracticable for manufacturing ceramic parts by slip casting.

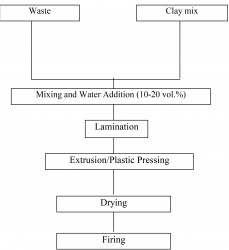

On the other hand, the excellent properties of the fired ceramic bodies based on shale clayey raw materials motivated the development of this method which involves the irreversible destruction of the clayey structure by calcination at temperatures ranging between 100 and 1000 ºC.

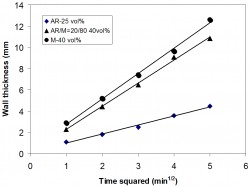

The calcined raw materials are ground and mixed with non-calcined raw material in proportions which may vary from 0-100%.

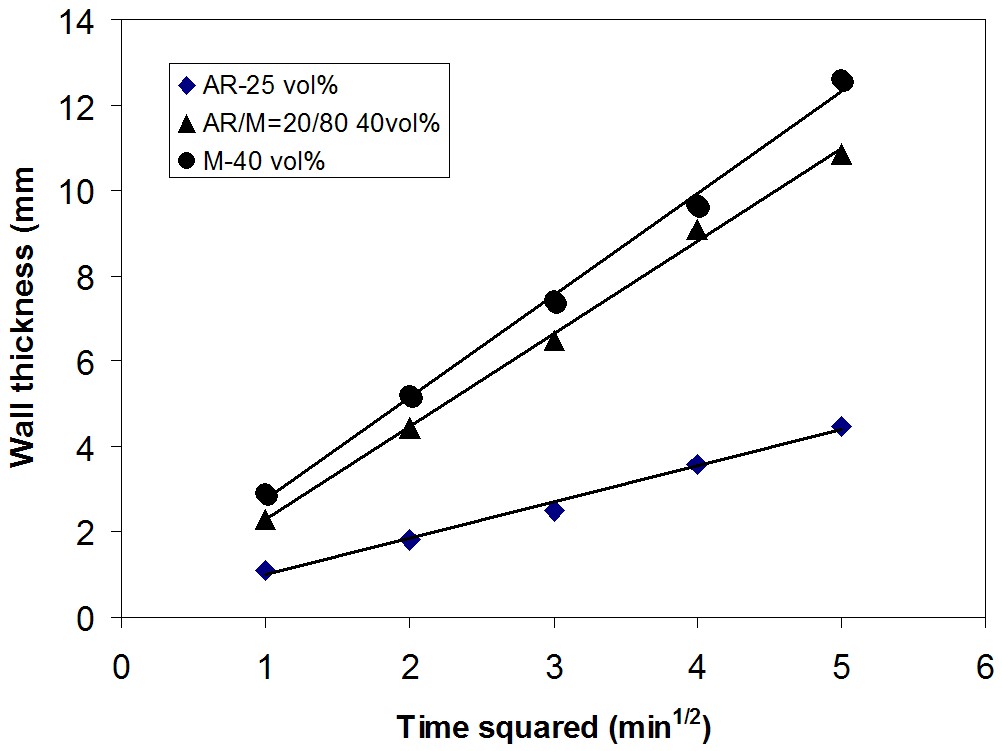

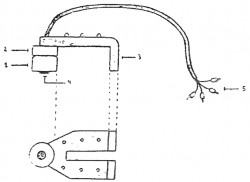

Suspensions of these mixtures with solids contents up to 50% by volume can be stabilized with inorganic salts, anionic or cationic polyelectrolytes or polymers added in percentages ranging between 0 and 3% by weight relative to the weight of solids.

Innovative aspects & main advantages

There are abundant deposits of clay rich sedimentary rocks in Brazil. A single raw material forms dense, strong and aesthetically attractive stoneware ceramic products upon firing at about 1100 ºC. But its mineralogical nature [smectites (bentonite, illite, montmorillonite), and paligorskites and sepiolites] and the fine size of particles make the kinetics of slip casting too slow, limiting the processing routes to dry and plastic forming techniques. The present invention makes the wet forming techniques (slip casting, pressure casting, etc.) viable enabling the fabrication of complex shaped products.

Applications

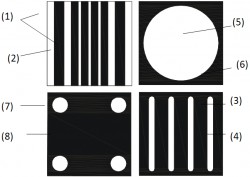

The accentuated red color and the excellent properties of the ceramic parts fired at moderate temperatures of the order of 1100 ºC (high bending strength, virtually no water absorption) opens up a wide range of possibilities of industrial applications for the method now proposed. In particular, the method has enormous advantages for the production of all kinds of hollow and complex shaped parts such as tableware (tableware, tea and coffee), a wide range of decorative items, sanitary ware (some manufactures in Brazil produce red sanitary ware). In Portugal and in Europe, the toilets are usually manufactured in “white” ceramic pastes, because of market idiosyncrasy reasons. A good designer could find interesting solutions for red sanitary ware integration, which could be glazed inside, while displaying outwardly its rustic appeal.