Abstract

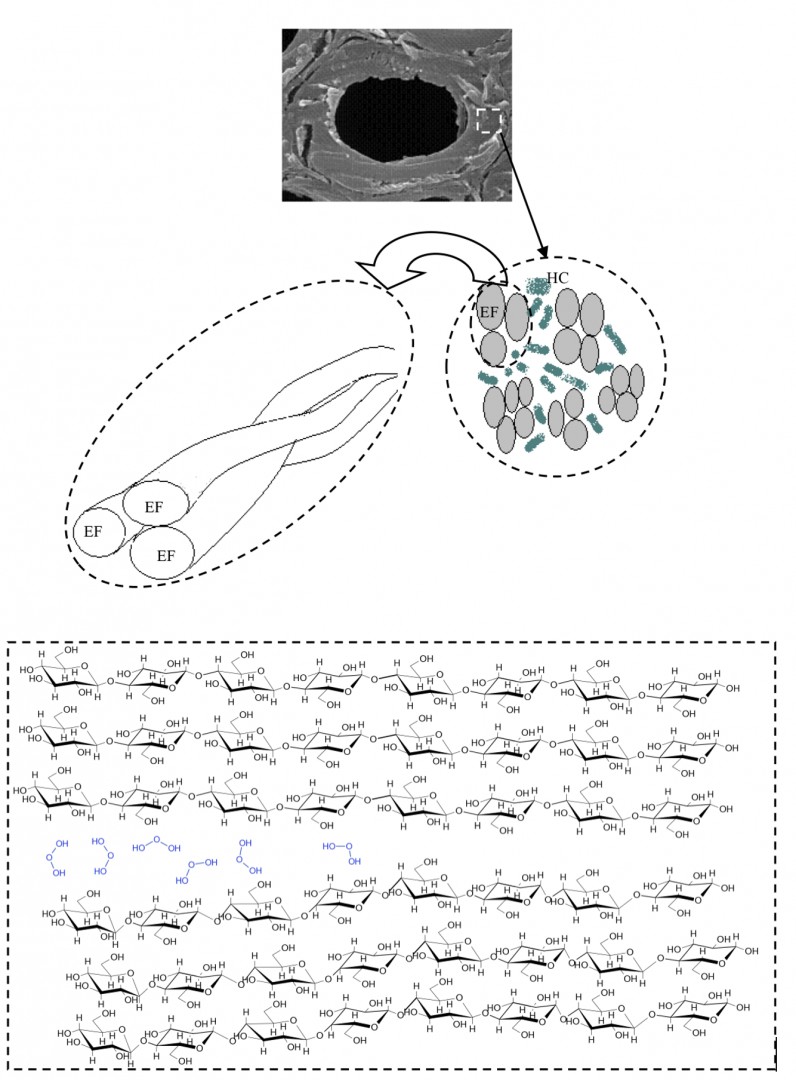

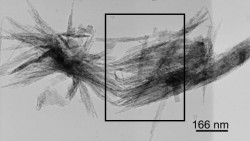

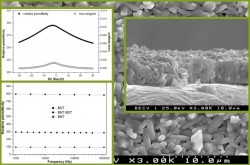

The present invention relates to a method for modifying the properties of cellulose pulps. Said method consists of modifying the properties of cellulose pulps by means of cold/hot processing with the application of high hydrostatic pressure (100-1000 MPa) at temperatures between 0-100 ºC for a time period of between 1-75 minutes (or possibly longer). Said method can be used for any type of cellulose pulp, preferably in aqueous medium, with a consistency in the range of 0.1-40.0%. In treated pulps, the cellulose undergoes structural changes and amorphous cellulose accessibility increases. Said method improves pulp hydration due to the incorporation of water molecules which bind strongly to the cellulose. When previously dried pulps are processed, the swelling capability of said pulps is restored and problems relating to hornification are reduced. The structural changes that occur to the cellulose increase intrinsic fibre strength, and the hydration that occurs improves fibre flexibility, elasticity and bonding ability. The physical properties of the processed pulps are significantly improved, without decreasing the bulk of same. Consequently, it is possible to produce pulps with modified and improved properties, for various uses, particularly as raw material for the paper industry or as an excipient for the chemical, food and pharmaceutical industries.

Innovative aspects & main advantages

The technique of the hydraulic hyper pressure was applied for the first time for the modification of cellulosic pulps. The processed pulps undergo structural changes and exhibit increased accessibility to the amorphous domains and to the interfibril space. This process leads to the incorporation of strongly bound water into the cellulose structure, improving the hydration of pulp. The hyperbaric treatment of previously dried pulps restores its swelling ability thus reducing the hornification problem. The structural changes undergone by cellulose increase the intrinsic strength of the fiber, while the forced hydration provides greater flexibility, elasticity and binding capacity to fibers. The physical properties of processed pulps improve significantly without loss of the paper bulk. The high pressure treatment promotes the accessibility of fibers towards chemicals thus allowing the production of pulps with enhanced properties for a wide range of applications.

Applications

The hydraulic hyper pressure processing of the cellulosic fibres may find various applications related to the production of advanced materials in the paper industry or as excipient in the chemical, food and pharmaceutical industries.