Abstract

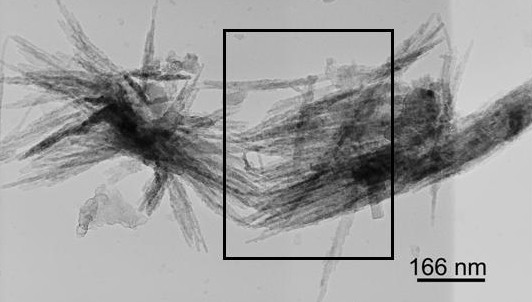

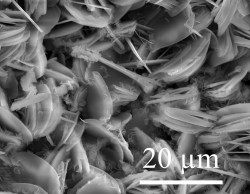

The present invention relates to a method of manufacturing new luminescent nanowires, nanostrings, nanorods and/or nanosticks of beryllium, magnesium, calcium, strontium or barium doped cerium (III) aluminates, which uses mechanical ultrasonic energy vibrations (ultrasonication), in addition to milling of precursor particles and re-firing. Such nanomaterials that can be co-doped with other elements of the lanthanide series, have a diameter between 1 and 300 nm and aspect ratio between 3 and 3000, with luminescence optics, photocatalytic, magnetic, electronic, and biological uses, being macro-, micro- or nano-functionalized, as well as, incorporated into a matrix to make new nanostructured composite materials.

Innovative aspects & main advantages

The present invention relates to a new method of manufacturing luminescent nanowires and nanorods of alkaline earth aluminate aluminates (Be, Mg, Ca, Sr, Ba) luminescent aluminates alkaline earth aluminate aluminates (Be, Mg, Ca, Sr, Ba) doped cerium (III), which may be co-doped with other elements of the lanthanide series. The method combines grinding and ultrasonic energy to generate and activate the precursor particles, followed by s suitable heat treatment.

Applications

The nanowires and nanorods are interesting nanomaterials for applications in optoelectronics, photovoltaic cells, biomedical devices and biosensors (drug release, cell detection, diagnostic imaging, loading of DNA structures, etc.).