Abstract

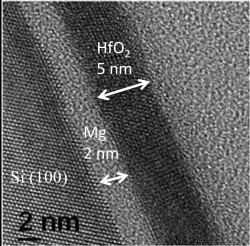

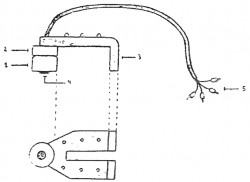

The present invention relates to the solidification process control technology of superconductive ceramic materials of the Bi-Sr-Ca-Cu-O system by Laser-Floating-Zone (LFZ) through application of electric current during fibers growth.

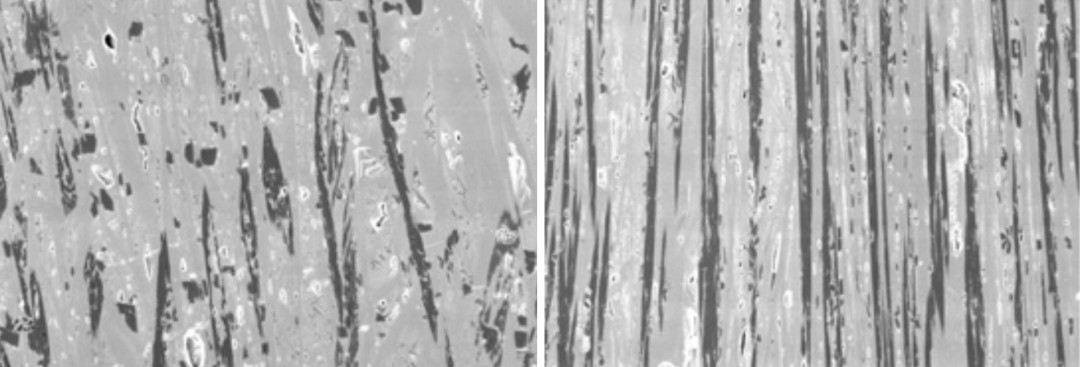

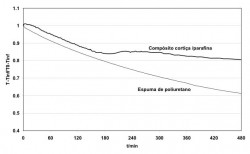

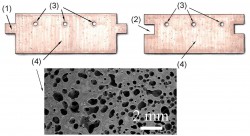

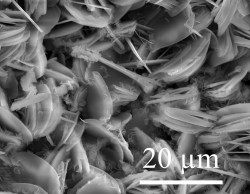

The high thermal gradient associated with the LFZ technique results in a partial alignment of the crystals, which is significantly increased by passing an electric current through the melt zone.

The solute transport in the solidification interface is stressed by the electromigration phenomenon, resulting, in predefined conditions, in a higher degree of texture and a crystals size and interdendritic distance refinement.

ly increase the critical current density of superconducting fibers, a crucial property for technological applications. Additionally, the electrical signal through the melt zone becomes available for the process automatic control, allowing the production of single or multifilament devices by optical division of the laser beam.

Innovative aspects & main advantages

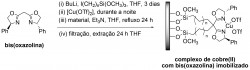

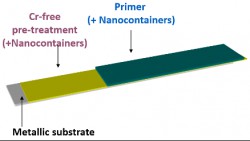

The invention consists of a new technology to control the solidification process of superconducting ceramic fibers of Bi-Sr-Ca-Cu-O system by assisting the laser floating zone technique with an electric current during fiber growing. Its main advantages are: i) to obtain highly crystallographic orientated materials; ii) to increase the superconducting properties, namely the critical current density; iii) to allow the simultaneously growth of one or multiple filaments from optical division of the laser beam.

Applications

Electrical energy transport and storage industries; electronic devices.