Abstract

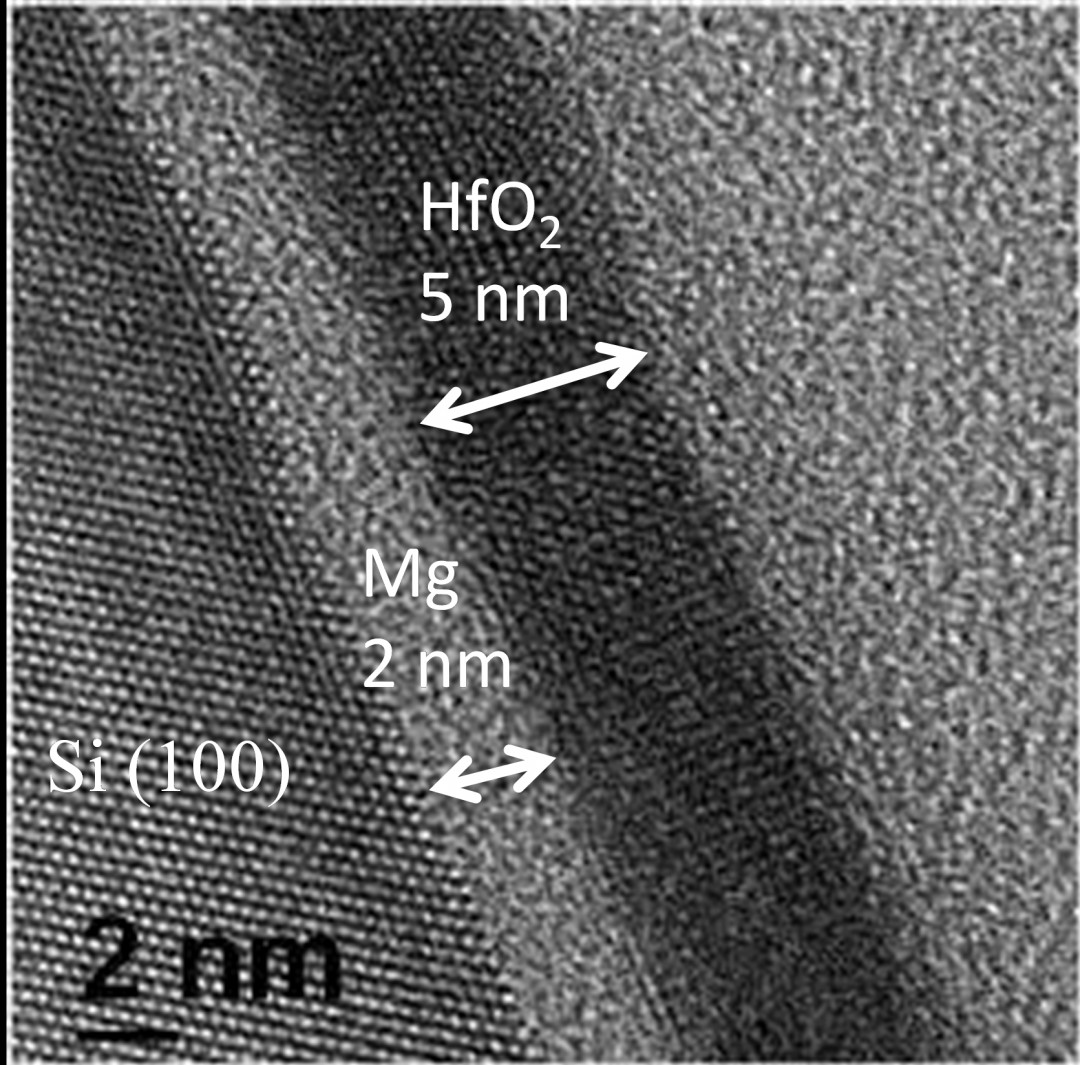

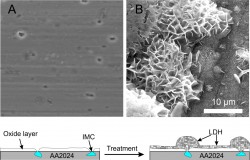

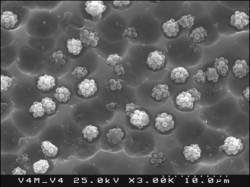

The present invention provides a method for the production of microelectronic devices that uses a thin metallic Mg layer as oxygen diffusion barrier. This method prevents the oxygen diffusion into the substrate during the growth process of oxide thin films and/or prevents the oxygen escape from the substrate into the processing environment allowing thus a complete control of the oxygen stoichiometry and/or oxidation during the production process of the microelectronic device. If necessary and/or convenient the Mg thin layer can be diffused into the adjacent layers by thermal treatment.

Innovative aspects & main advantages

The use of interlayers in the manufacture of electronic devices is made towards preventing the passage of oxygen to the metallic electrode and thus its oxidation. With the increasing miniaturization of electronic components, the use of interlayers is subject to its diminution, following the scale miniaturization of these components. Hafnium, amide precursors, ALD non-aqueous, other deposition techniques such as MBE, replacement of SiO2 dielectric ultra-thin nitrided SiO2 interlayers and nitride deposed, among others, are some of the solutions that have been tested over the past years, all showing deficiencies at various levels. This technology presents a new approach with the following advantages:

Conformal coating of an HfO2 thin film on top of the silicon substrate without intermixing between the interlayer and the oxide thin film on top without gradient due to change in density;

Improvement of the electrical properties after post-deposition annealing;

Presence of charges only due to the deposition technique we used for the deposition of the high gate dielectric (ALD).

Applications

Electronic components for various types of hardware.