Abstract

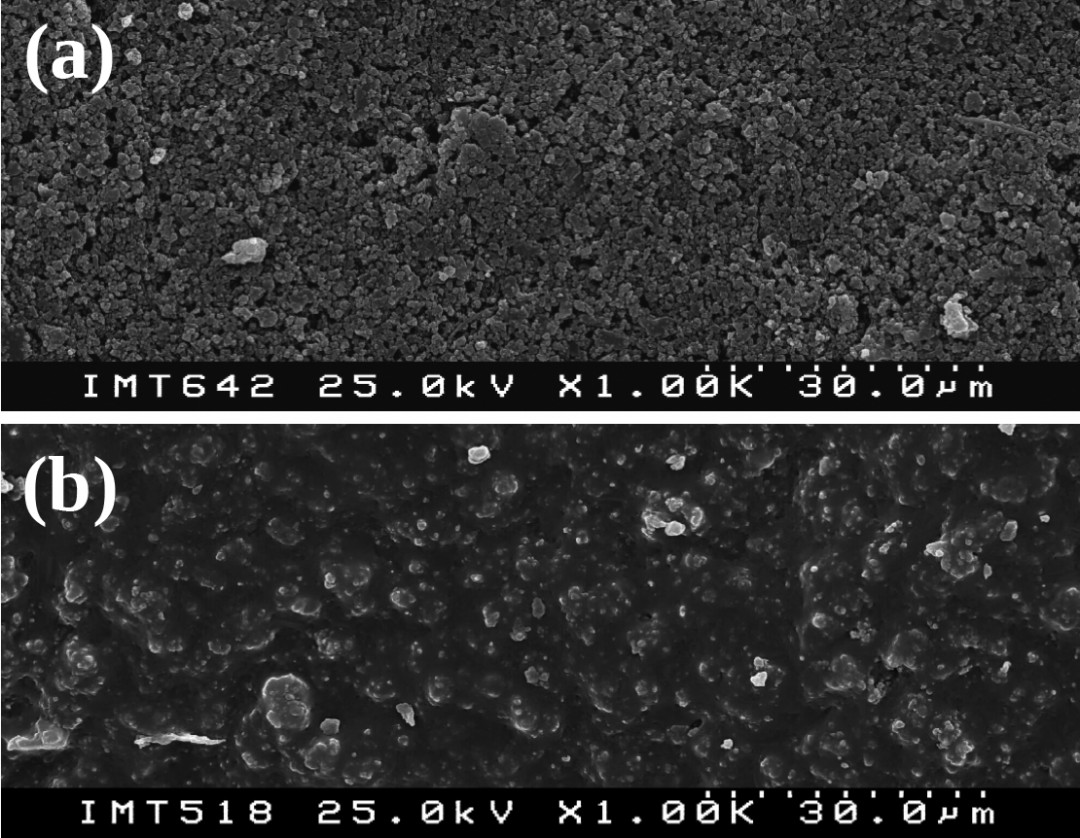

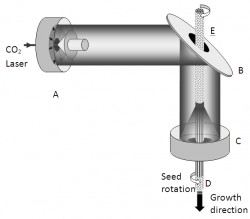

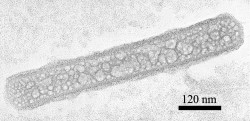

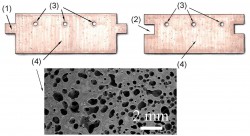

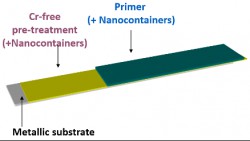

The present invention relates to a method of manufacturing substrates for high packaging circuitry in microelectronics, consisting of cordierite-based glass-ceramic materials, characterized by having low values of dielectric constant and dielectric loss factor, from mixtures of cordierite powder and a borosilicate glass dispersed in an aqueous media with the help of dispersing agents, of anionic and/or cationic nature and aqueous emulsion binders in order to obtain suspensions with optimum rheological properties for the tape casting process onto an appropriate support, ensuring a good behaviour during drying under controlled temperature and humidity conditions as well as a good compromise between the mechanical properties of green tapes (hardness and flexibility, and resistance to tensile stress), which can be co-sintered at relatively low temperatures (~1000 °C) with low melting point metal pastes.

Innovative aspects & main advantages

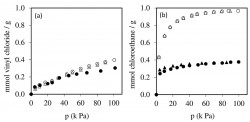

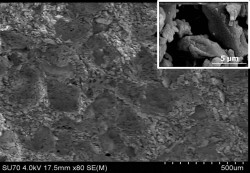

Cordierite-based ceramics are very promising materials as substrates for microelectronic applications due to their excellent dielectric properties (dielectric constant, ε~5 at 1 MHz with a low dielectric loss). But cordierite is difficult to densify and has poor mechanical properties. The mixture borosilicate glass with the stoichiometric cordierite solves these difficulties, and permits co-sintering with metallic pastes. The tape casting process in aqueous medium is healthier, safer, more environmentally friendly and less expensive when compared to the use of organic solvents.

Applications

Cordierite-based glass-ceramic substrates with their excellent dielectric properties (dielectric constant, ε~5 at 1 MHz with a low dielectric loss) for microelectronic applications.