abstract

This work is on processing and studying of toughening property of indentation fracture composites. By applying reactive melt infiltration method infiltrated composites were prepared where different Si-Al compositions and as-pressed porous boron carbide were used at various infiltration temperatures. In which the process became feasible within the experimental constrains of this task. Polished sections of infiltrated composites were examined by quantitative methods with standards for the volumetric fractions of B4C, Si, Al, and SiC crystalline phases; and the element distribution in the phases were investigated by SEM/EDS, represented through ternary phase diagram. The distribution of ductile aluminium and brittle phases could determine the means of toughening mechanism and further discussed the de-bonding of interphases. (C) 2019 Elsevier Ltd. All rights reserved.

authors

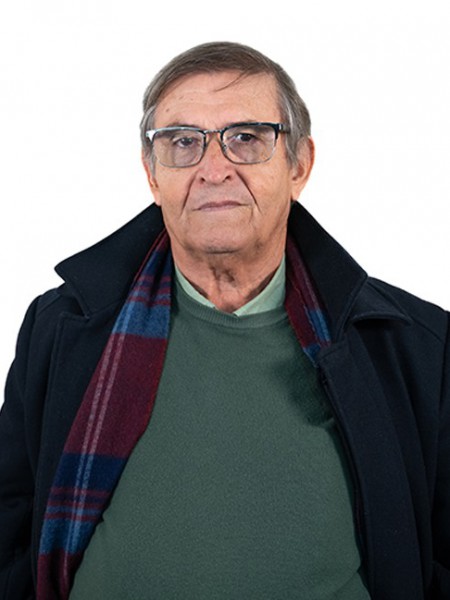

Ravanan, A; Vieira, JM; Almeida, BA; Ramkumar, C; Oliveira, FJ; Lopes, AB; Wu, HY

our authors

Groups

G2 - Photonic, Electronic and Magnetic Materials

G3 - Electrochemical Materials, Interfaces and Coatings

acknowledgements

The authors would like to acknowledge the RNME - Pole University of Aveiro (FCT Project REDE/1509/RME/2005) for access to SEM microscopy, and one of the authors was funded by EMMS consortium of European Union Commission for the M.S.-scholarship.