Description

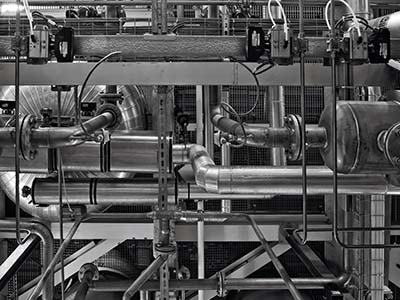

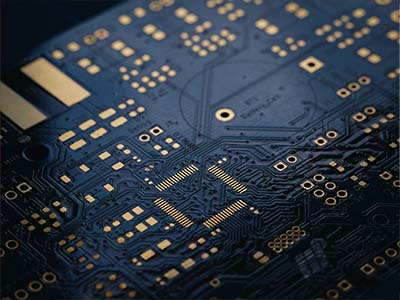

The developed project allowed the acquisition of two pieces of equipment: a high temperature graphite furnace (max. 2000ºC) of semi-industrial size with controlled atmosphere, for sintering of ceramic composites, and an universal mechanical testing machine for flexural, compressive and creep characterization up to 1400°C of those materials in controlled atmosphere. These new facilities were associated to Group 5 (Ceramic Composites and Functional Coatings for Structural Applications) of Line 2 (Advanced Materials for Industrial Applications) of the Aveiro University Associated Laboratory CICECO (Centre for Research in Ceramics and Composite Materials). Several applied research projects (8 funded projects by FCT, ADI, GRICES and European Union) beneficiated from these acquisitions and 3 partnerships with industrial companies involved in the fabrication of metallic and non-metallic materials were strengthened. The main processed and tested materials were the silicon nitride (Si3N4) based ceramics uncoated or coated with CVD (chemically vapour deposited) diamond. These materials can be used in high wear resistance applications, as is the case of mechanical seal components and cutting tools, or where biocompatibility must be granted, like in articular joints or orthopaedic and orthodontic tools. The work done led to the publishing of more than 50 scientific papers, 2 patents, 3 PhD thesis and 5 MSc dissertations.

Coordinator

Coordination

Universidade de Aveiro (UA)

Partners

no

Groups

G3 - Electrochemical Materials, Interfaces and Coatings;

G2 - Photonic, Electronic and Magnetic Materials;

Sponsors