Abstract

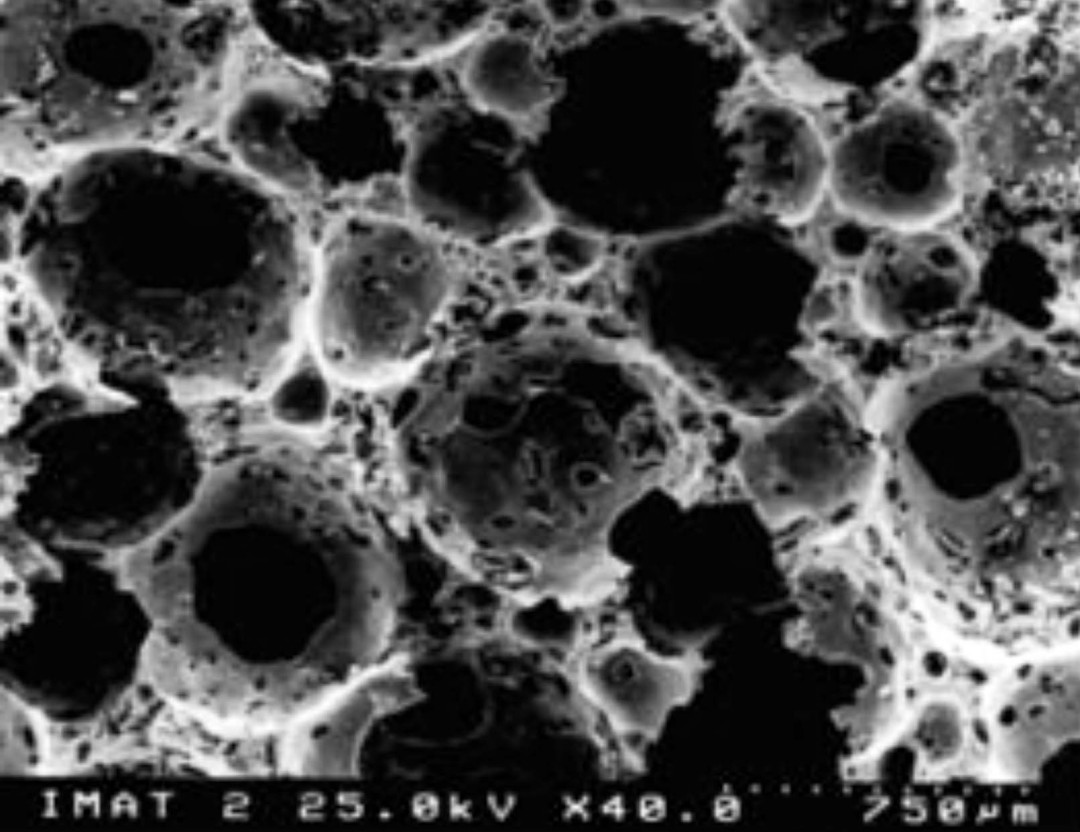

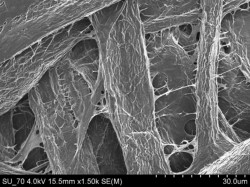

The present invention relates to a new process for manufacturing macroporous ceramics with average pore sizes greater than 100 microns and porous structures suitable for a variety of applications as bone grafts, filtration, thermal insulation, gas burners, catalyst supports, etc.

The process relies on the addition of surfactants and foaming forming agents, and of starch based materials, to a suspension of the ceramic material.

Stirring the suspension results in the formation of abundant foam, which is then strengthened by heating due to gelling starch action.

The subsequent combustion and sintering of the organic substances allows obtaining the porous structures with high degree of interconnectivity.

Innovative aspects & main advantages

The present invention is a follow up of the Portuguese Patent # 101 910 of 29.08.96, in which starch granules were firstly used as pore formers and direct consolidation agents of ceramic suspensions. However, the size of the pores formed, limited to the size of the starch granules, is considered insufficient for the intended applications that motivated the development of the present invention, such as filtration, gas burners and implantology. Therefore, foaming agents were used to generate large pores. Moreover, excepting the Portuguese Patent # 101 910, to which the present invention is a natural continuation, no other patent proposed the use of starch as the consolidating agent. The present invention combines the advantages of gelation of the starch to fix the structure of foams formed by pores of several hundreds of micrometers, being novel and exceeding the state of the art.

Applications

The porous structures formed by the patented method can find applications in several fields, including filtration, gas burners, thermal insulation, and implantology when fabricated from bioactive and resorbable materials suitable as bone graft substitutes.