Abstract

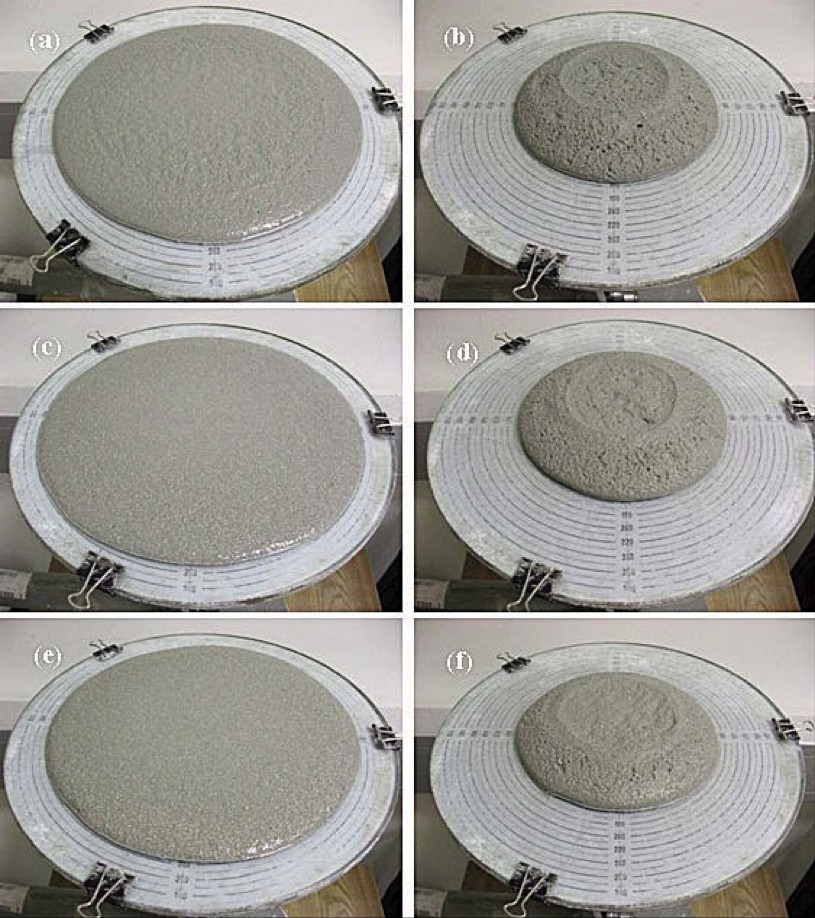

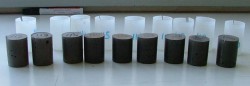

The present invention relates to the use of sludge generated in the process of filtration and treatment of potable water as a workability adjuvant (setting retarder) of industrial mortars, in replacement of bentonites with a high commercial value. The proper operation control of water treatment system ensures reasonable consistency of properties in terms of particle size and chemical composition. The sludge can be used as it is processed or after prior drying, and after addition of sodium tripolyphosphate (up to 25% by weight).

Industrial mortars formulations containing sludge up to 0.5% have setting times comparable or even greater than industrial formulations to which bentonite has been added. Also the manipulating range in the fresh state is compatible with needs. This solution also presents environmental added value, translated in the recycling of waste in the form of high commercial value additive.

Innovative aspects & main advantages

The slurry generated in the process of filtration of water is used as an additive in the work activity of mortar employed for coating or facing operations, as a retarder of hardening, in industrial monolayer rendres, in substitution of bentonites of high commercial value, correct control of the function of the water treatment system, ensuring the reasonable constancy of properties in terms of granulometry and chemical composition.

The slurry can be used as such and processed or after prior drying, to which is added up to 25 per cent by weight of sodium tripolyphosphate. Industrial formulations containing up to 0.5 per cent slurry present hardening starting times comparable to or even greater than industrial formulations to which bentonite has been added. The manipulating period in the fresh state is compatible with necessities. This solution presents even more ambiental merits, translated into the recycling of a residue comprising an additive of high commercial value.

Applications

The main application of this invention (the potential commercial/industrial sectors) is focused on the producers of sludge (as an alternative to landfill) and to mortar and concrete producers (as end users).